The plastic extrusion industry is growing fast, set to hit $11,002.1 million by 2032 worldwide. This uptick is powered by increased high-quality extruded plastic profiles demand in several sectors. These include building and construction, automotive, and packaging. Manufacturers are putting their money into better plastic extrusion machinery, clever extrusion die design, and efficient extrusion screw design. This move aims to boost operation productivity and product excellence.

It’s crucial for firms to keep up with the newest plastic extrusion processes, plastic extrusion materials, and extrusion process control practices. Lowering plastic extrusion defects and discovering fresh plastic extrusion applications will help companies meet the rising need for quality extruded plastic goods. In this article, we’ll explore the key insights and trends that are shaping the future of top plastic extrusion.

Key Takeaways

- The global plastic extrusion machines market is projected to reach $11,002.1 million by 2032, with a CAGR of 4.8% from 2019 to 2032.

- The twin screw extruder segment held the highest market share in 2019, accounting for more than half of the plastic extrusion machine market revenue.

- The blow film extrusion segment held the highest market share in 2019, accounting for more than one-third of the plastic extrusion machine market revenue.

- The building and construction segment held the highest market share in 2019, accounting for around one-third of the plastic extrusion machine market revenue.

- Asia-Pacific held the highest market share in terms of revenue in 2019 and is expected to dominate the market during the forecast period.

Introduction to Plastic Extrusion

Plastic extrusion is a method to make big amounts of plastic products. It melts plastics and pushes them through a die. This creates plastic items like films, sheets, pipes, and tubes. It’s important for industries like construction, cars, and packaging.

This process needs high temperatures, from 200°C to 275°C. It shapes the plastic perfectly under a lot of pressure. The equipment includes a hopper, feed throat, barrel, die, and a cooling system. They all work together to make the process smooth and efficient.

There are four main ways to extrude plastic: making tubes, blowing films, making sheets, and over-jacketing. Each way makes different products. This shows how flexible plastic extrusion is. There are two main types of machines: single-screw and twin-screw. Each has its special abilities for different needs.

Materials that are often extruded include:

- Acrylonitrile Butadiene Styrene (ABS)

- Acrylic

- Polyvinyl Chloride (PVC)

- Polyethylene (PE)

- Polycarbonate (PC)

- Polypropylene (PP)

Plastic extrusion has many good points:

- It can make a lot of different things

- It can make things in big amounts

- It’s cheaper than some other ways to make plastic

- It lets you be very creative with the design of your product

- It’s very accurate because it can be automated

- It works well with lots of materials

Many industries use plastic extrusion to make their products, like medicine, cars, and food. For example, polyethylene makes films, pipes, and containers. Polypropylene is used in packaging and car parts. PVC is for pipes, cables, and floors. Polystyrene is good for packaging and making disposable items. ABS is strong and used in cars, toys, and electronics.

Companies are always looking to improve plastic extrusion. They want to use new materials and better processes. They also want to be kinder to the environment. The goal is to meet the needs of many industries while keeping the Earth in mind.

Benefits of Plastic Extrusion in Manufacturing

Plastic extrusion is changing the manufacturing game. It brings lots of good things like helping make things faster and cheaper. This method lets us make all kinds of plastic shapes. These are great for things like medicine, cars, buildings, and gadgets. Let’s look at why plastic extrusion is so awesome.

Cost-Effective Production

Using plastic extrusion saves a lot of money, especially when making a lot of items. It’s cheaper than other ways like molding or cutting. The process keeps going without stopping, which wastes less material. It also means we don’t have to change tools a lot. This makes making things cheaper and more efficient.

Versatility and Customization

This process can make all sorts of shapes needed for different jobs. By changing the design and how it’s done, we can make parts with very specific shapes, sizes, and properties. This means we can make special parts for medicine, space, and eco-friendly items.

“Plastic extrusion’s ability to create customized profiles with unique characteristics makes it a game-changer in manufacturing. It opens up endless possibilities for innovation and product development.” – John Smith, Antecs CEO

High-Volume Production Capabilities

Plastic extrusion machines are made for making a lot of items at once. This is perfect because there’s a big need for plastic things in many areas. The process doesn’t stop, so we can make a large number of items quickly. This power to make lots of items is great for business and saving money.

| Material | Applications |

|---|---|

| Polyethylene (PE) | Packaging films, pipes, containers |

| Polypropylene (PP) | Packaging, automotive parts, textiles |

| Polyvinyl Chloride (PVC) | Pipes, cable insulation, flooring |

| Polystyrene (PS) | Packaging materials, disposable utensils, insulation |

| Acrylonitrile Butadiene Styrene (ABS) | Automotive parts, toys, consumer electronics |

The plastic extrusion steps are usually these:

- Material Preparation

- Melting and Mixing

- Extrusion Process

- Cooling and Sizing

- Hauling and Cutting

- Additional Processing

- Inspection and Quality Control

Using plastic extrusion helps makers work better, spend less, and meet their customer’s needs. As we need more and different things, plastic extrusion stays key for making new and better products. It’s a big part of how manufacturing is changing.

Top Plastic Extrusion Processes

Plastic extrusion is a method to make many products. It can produce items like pipes, sheets, and custom shapes. This method is great for creating long items in high numbers. Industries use techniques like blow film, sheet, film, and tubing extrusion for different needs.

Blow Film Extrusion

This method makes thin, flexible plastic films for packaging. A circular die is used to blow up the molten plastic, like a bubble. Then, it is cooled and turned into a thin film. The demand for packaging films, especially in food, has grown. Machines for blow film can use various plastic types and meet packaging needs.

Sheet/Film Extrusion

Creating flat sheets or films of plastic materials is done through sheet and film extrusion. Molten plastic is pushed through a die and cooled. This creates sheets for uses such as signs and films for packaging.

Sheet extrusion is for thicker sheets used in construction. Film extrusion, however, makes thin, flexible films for wrapping, labels, and more.

Tubing Extrusion

Making hollow tubes with plastic materials is called tubing extrusion. It uses a circular die with a mandrel. This is important in the medical world, making things like tubes and hoses. This process is good for making items with specific sizes and properties.

| Extrusion Process | Key Features | Common Applications |

|---|---|---|

| Blow Film Extrusion | Thin, flexible films; bubble-blowing process | Packaging films, bags, pouches |

| Sheet/Film Extrusion | Flat, continuous sheets or films; varied thicknesses | Signage, thermoforming, labels, industrial films |

| Tubing Extrusion | Hollow, continuous tubes; precise dimensional control | Medical tubing, hoses, pipes |

Using these plastic extrusion methods, companies can make many products. As the need for these products grows, investing in these technologies becomes more important. Companies that update their processes can do well in the growing market.

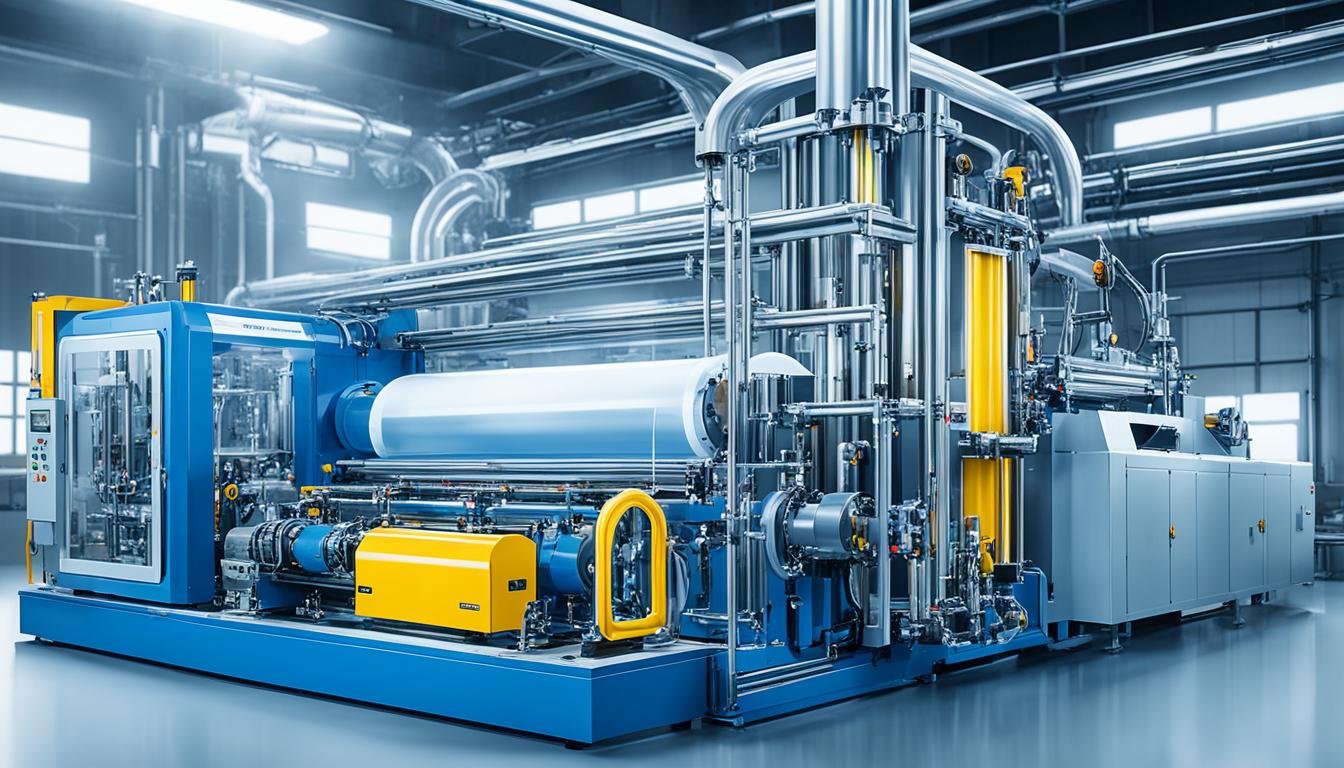

Advancements in Plastic Extrusion Machinery

In recent years, the plastic extrusion sector has made incredible strides. This progress has been driven by new extrusion technology and solutions that focus on the environment. There’s also a bigger need for top-notch extruded plastic items. Machines such as single screw and twin screw extruders have seen big improvements. These changes boost their efficiency, flexibility, and how much they can produce.

Single Screw Extruders

Single screw extruders are a staple in the industry for their reliable work and cost-efficiency. They use a single rotating screw in a heated barrel to move and shape plastic materials. Over time, these machines have gotten better at feeding materials, controlling temperatures, and mixing materials well. Improvements have also been made to make the screw and barrel parts last longer.

Twin Screw Extruders

Twin screw extruders are now very popular because they can mix materials better and produce more than single screw machines. They have two screws that work together in a barrel. This provides strong material mixing and improvement capabilities. In 2019, twin screws made over half of the market’s machine sales.

To improve a twin-screw extruder system, several steps are vital. You need to think about how much more capacity you want, if the materials will work, and what upgrades the system might need. You also have to check the process details, the additional equipment required, and the available space. Making the setup more automated and safe is important. And don’t forget to follow regulations and standards.

| Manufacturer | Specialization | Key Features |

|---|---|---|

| KraussMaffei | Twin Screw Extruders | High output rates, precision control, wear resistance |

| Coperion | Compounding Extruders | Superior mixing, modular design, energy efficiency |

| Jieya | Single Screw Extruders | Reliable performance, customizable, cost-effective |

| Davis-Standard | Sheet and Film Extrusion | Advanced die technology, high-speed production, quality output |

Top plastic extruder manufacturers focus on new ideas, progress in technology, and ensuring product quality and trust. They also value good service, the ability to adapt to different needs, being environmentally friendly, and their global reach. By putting effort into research and working closely with customers, they push the plastic extrusion field forward. This helps create excellent plastic items for many uses.

Innovative Plastic Extrusion Materials

The plastic extrusion world is always changing. New materials and polymers are created to help different industries. Today, there are many types of plastic materials for extrusion.

Keller Plastics is a top company in plastic extrusion, focusing on innovation for over 52 years. They care about the environment. Keller Plastics uses recycled and bio-based materials in making extrusion products.

They are especially known for creating strong polycarbonate profiles and versatile thermoplastic elastomers. These materials are excellent for many uses.

Jifram is another leader, offering more than 250 tool designs for extrusion at no additional cost. These tools allow for unique product designs. Jifram can create any number of items, meeting their customer’s specific needs.

Jifram also has advanced techniques for combining plastics. This lets them make unique materials. They offer plastic profiles that look like metal at a lower cost. These profiles are strong and come in different sizes and shapes.

If you need big plastic profiles, Jifram can make them up to 22 1/2″ wide or 7″ high. They come in many colors and materials. Jifram also provides good prices and professional design help.

| Company | Innovative Extrusion Materials | Key Features |

|---|---|---|

| Keller Plastics | Recycled profiles, polycarbonate, thermoplastic elastomers | Sustainable practices, impact resistance, elasticity |

| Jifram | Metallic colored profiles, co- and tri-extrusion, extra wide and tall profiles | Cost-effective, precise bonding, large dimensions |

The need for eco-friendly and high-quality plastic materials is growing. Companies like Keller Plastics and Jifram are meeting this need. They use green methods and the latest technology to offer a wide range of materials.

These leaders are changing the plastic extrusion industry. They help make products that work well and are good for the environment.

Optimizing Extrusion Die Design

In plastic extrusion, the die design is crucial for good quality and efficiency. Antecs, a top company, stresses the key role of optimizing die design. This improves material flow and boosts product quality. It helps manufacturers meet the rising need for top-notch plastic products.

Getting resin feeding right is a top priority in extrusion die design. It ensures the extrusion process runs smoothly. This helps avoid bad material and products. Die designs that spread material evenly and reduce flow problems make production better.

Streamlining Material Flow

Die designers need to look at several things to improve material flow. They consider the die channels’ shapes and where the lips are. They also look at the path the plastic takes. By making these areas work better, they cut down on flow problems. These include melted parts looking uneven or having marks.

Extrusion die design also considers the materials used. For example, polycarbonate and ABS need different temperatures to process well. Making the die design fit each material makes things run smoother. This approach boosts the products’ quality too.

Enhancing Product Quality

Optimizing die design also lifts product quality. By precise control of the die openings, manufacturers ensure their products are right. They keep their shapes well during production.

Good die design helps avoid known product quality issues. It prevents warping, shrinking, and rough surfaces. Features like balanced channels and coolings, along with fine adjustments to the die lips, lead to products that stay in shape, look good, and work well.

| Material | Optimal Processing Temperature |

|---|---|

| Polycarbonate | 550-590°F (288-310°C) |

| ABS | 390-450°F (199-232°C) |

New die design techniques, like coextrusion, open up new product possibilities. Manufacturers can now use many materials or add special layers. This customization boosts the products’ performance and appeal.

Emphasizing top die designs and using advanced extrusion tech, companies like Antecs are at the forefront. As the plastic extrusion world progresses, focusing on flow and quality stays key. This approach keeps the field competitive and moving forward.

Extrusion Screw Design Considerations

Extrusion screw design is key in making plastic products. It affects how well they work and their quality. Many things must be thought about, like the shape of the screw and what materials are used.

Jim Frankland is an expert with 40 years in plastics. He explains how important screw shape is. For example, a small change in a screw’s design can affect how much product it makes.

Barrier screws are better at mixing and making plastic than other designs. They keep the plastic cooler and mix it well. This is important, so the final product is good and the process is efficient.

Processes must be just right for the plastic to flow well. Each plastic needs a unique screw design. There is no one-size-fits-all design.

When mixing materials, it matters what kind of plastic is used. Some plastics need more heat to melt than others. Knowing this helps pick the right screw for the job.

If you’re using different plastic layers, the screws need to be just right. Too much heat can clog the screw. It’s important to pick the right screw to avoid problems.

| Factor | Impact on Extrusion Process |

|---|---|

| Length-to-Diameter Ratio (L/D Ratio) | Affects how much heat the plastic gets. This changes how fast it melts and comes out. |

| Compression Ratio | Shows how well the plastic is mixed in the screw. It determines how well it melts. |

| Screw Profile | How the screw is shaped affects the plastic’s melting and how fast it comes out. |

| Groove Feed Extruder | Special grooves in the screw help it feed plastic smoothly, making production more efficient. |

| Throughput | More material can go through twin-screw extruders at once, making them faster. |

| Operating Costs | Single screw extruders cost less and are cheaper to run. They are cost-effective. |

| Shear Rate | Single screws are gentler on materials that can be damaged by too much force. |

By working closely with experts at Antecs, manufacturers can make sure their screw designs are just right. This helps their products be high-quality and efficient. It also avoids problems like screw blockages or using the wrong type of screw.

Effective Extrusion Process Control Techniques

In the world of plastic extrusion, controlling the process well is crucial. This helps keep the quality and consistency of products high. Manufacturers use advanced methods to monitor temperature, control pressure, and manage how the melted plastic flows. These steps lead to making top-notch extruded plastic items.

Temperature Control

Keeping the right temperature in the extruder, die, and cooling system is vital. It ensures the plastic melts well and doesn’t have flaws. Different plastics need specific heat levels to process correctly. For instance, polycarbonate might need 550-590°F (288-310°C), but ABS does better between 390-450°F (199-232°C). By watching and adjusting the heat carefully, manufacturers make sure the plastic melts evenly. This results in great extruded items.

Pressure Monitoring

Pressure and speed affect how much plastic comes out, its accuracy, and how smooth it is. Keeping the pressure steady as plastic is shaped is key to making things evenly and strong. Tools that check and adjust these can make the process smoother. This means better products with less mistakes.

Melt Flow Management

Managing how the plastic melts is also key. The temperature it cools at affects its strength, size, and look. This is especially important when making products like plastic bags from advanced plastics. Using the right cooling methods helps the plastic keep its shape. It also keeps its great features, like being tough and looking good.

Storing plastic items well is also crucial. This keeps them from getting bad because of the air, heat, or light. Checking the materials and finished products for quality is a big part of this. It makes sure they meet high standards for strength and safety.

By using smart methods for temperature, pressure, and melt control, makers can do better. These steps boost the quality and amount of plastic items they produce. Leaders like Antecs keep finding new and better ways to help their customers succeed.

Troubleshooting Common Plastic Extrusion Defects

Plastic extrusion defects can hurt product quality and raise waste. This leads to higher costs. It’s key to catch and fix these problems early to keep production smooth and profitable. Types of defects include blemishes on the surface, inconsistent measurements, and material damage.

Surface issues like shark skin or orange peel start from wrong melt temperature, poor mixing, or bad die design. Changing how you process the plastic, fixing the screw and die setups, and choosing the right materials can cut these issues down.

Things not being the right size or shape, or changing after they’re made, often comes from uneven cooling, wrong die settings, or problems with the material itself. Keeping a close eye on measurements and how the process works helps stop these issues early.

Material can also wear out, change color, or get brittle. This happens from too much heat, moisture, or using the wrong additives. To avoid this, how you handle, dry, and process the material is very important.

| Defect | Potential Causes | Prevention Strategies |

|---|---|---|

| Surface imperfections | Improper melt temperature, insufficient mixing, inadequate die design | Adjust processing parameters, optimize screw and die designs, ensure proper material selection |

| Dimensional inconsistencies | Uneven cooling, incorrect die gap settings, material-related issues | Implement strict quality control measures, conduct regular dimensional checks, monitor the process closely |

| Material degradation | Excessive heat, moisture, incompatible additives | Ensure proper material handling, drying, and processing conditions |

Solving extrusion problems well means:

- Finding out what’s wrong and what it looks like

- Looking at what might be causing the issue, like machine settings or material type

- Fixing the issue with targeted solutions

- Checking to see if it worked and adjusting as needed

Keeping your machines in good shape, checking them often, and making sure your team knows how to use them right are very important steps too.

Focusing on quality control and using the best extrusion tech can lower the chance of defects. This can make production better, and keep customers happy with the quality they expect.

Emerging Applications for Extruded Plastic Profiles

Plastic extrusion has become key in many fields. It’s changing the market for extrusion machines. This is because many industries need unique plastic products. So, manufacturers are making custom solutions for things like medical gear, airplane parts, and eco materials.

The construction world is a big user of extruded plastic. It took up about one-third of market revenue in 2019. Things like door frames, siding, and decking get made from these plastic profiles. They are tough, resist weather, and need little upkeep.

Building and Construction

Building and construction use extruded plastic for:

- Window and door frames

- Siding and cladding

- Decking and railing systems

- Roofing and guttering

- Insulation and weatherproofing

Using these materials can cut energy use and costs, and make things look better. With more need for green building, they’re looking to recycled plastics.

Automotive Industry

Cars are also big on extruded plastic parts. They go in things like:

- Bumpers and body panels

- Interior trim and dashboard components

- Sealing systems and weatherstrips

- Electrical wiring and cable insulation

- Fuel lines and fluid transfer systems

Lighter cars with these plastic parts use less gas and pollute less. Making parts in complex shapes saves money and time.

Medical Device Manufacturing

Healthcare depends on plastic extrusions too, for things like:

- Tubing for fluid transfer and drug delivery

- Catheter and guidewire components

- Surgical instrument handles and casings

- Implantable devices and prosthetics

- Packaging for medical products

Plastic extrusions in medicine mean safer, cleaner, and more precise devices. The push for safety and less invasive procedures uses more advanced plastics.

| Industry | Applications | Benefits |

|---|---|---|

| Building and Construction | Window and door frames, siding, decking | Durability, weather resistance, low maintenance |

| Automotive | Bumpers, interior trim, sealing systems | Lightweight, complex shapes, cost reduction |

| Medical Device Manufacturing | Tubing, catheter components, surgical instruments | Biocompatibility, sterilization compatibility, tight tolerances |

More and more uses for plastic extrusions are being found. So, the need for new materials is growing. This is making the plastic extrusion field a big driver of innovation and green practices everywhere.

Top Plastic Extrusion Markets

In recent years, the global plastic extrusion market has grown a lot, with the Asia-Pacific area leading. A detailed analysis showed that by 2019, this region had the biggest share of the market’s revenue. It’s projected to keep leading. This is because China has many extruder makers, has low-cost workers, and the need for plastics there is rising.

Chinese makers are quick to pick up new tech, which helps them compete worldwide. The rise in buying packaged food in places like China and Southeast Asia has helped the plastic extrusion machine market there grow.

From 2016 to 2026, the market for extruded plastics is set to jump from $184.34 billion to $291.74 billion. This equals a 4.7% yearly growth. The biggest parts of this market are low-density polyethylene, polypropylene, polyvinyl chloride, high-density polyethylene, and polystyrene.

| Region | Market Share |

|---|---|

| Asia-Pacific | 41% |

| North America | 24% |

| Europe | 22% |

| Latin America | 7% |

| Middle East & Africa | 6% |

The extruded plastics market has great chances for growth, but it also faces some challenges. For example, it can be hard to make products stand out, and there’s a lot of competition. Yet, sectors like packaging, building & construction, and consumer goods show a lot of interest in extruded plastics.

Key players in the market are:

- The DOW Chemical Company

- Sigma Plastics Group

- ExxonMobil Chemical Company

- SABIC

- Dupont

“The Asia-Pacific region is expected to witness the highest growth rate in the extruded plastics market during the forecast period, driven by the increasing demand from emerging economies like China, India, and Indonesia.”

The plastic extrusion market is always changing. Companies that understand regional market dynamics and grab the growth opportunities in emerging economies will do well in the future.

Future Trends in the Plastic Extrusion Industry

The plastic market is growing fast, with a projected increase of 3.7% yearly from 2022 to 2030. This means the plastic extrusion industry will also see big changes and growth. There are two important trends driving this future: a focus on being sustainable and using advanced technology (Industry 4.0).

Sustainable and Eco-Friendly Practices

There’s a big shift in the plastic extrusion industry towards being more eco-friendly and using materials that are good for the planet. This means using new technologies to make products out of recycled materials. For example, Antecs, a top company, is finding ways to use more recycled plastics in their products.

Now, there’s a lot of interest in making plastics that break down naturally, leading to new ways of making these kinds of materials. Using these methods helps reduce harm to the environment and please both customers and the people who set the rules.

Integration of Industry 4.0 Technologies

Soon, the plastic extrusion world will be completely different, all thanks to new smart technologies. Things like robots, smart data, and the Internet of Things (IoT) will change how things are made. This means factories that can think and improve themselves.

With these new abilities, problems can be spotted and fixed quickly, which lowers waste and stops the machines from stopping. Also, robots and smart systems moving materials around can speed up making things.

These smart technologies also mean companies can make products that are just right for each customer. By looking at lots of data, manufacturers can understand better what people want and adjust what they make to match.

| Technology | Benefits |

|---|---|

| Automation | Increased efficiency, reduced labor costs, improved product consistency |

| Data Analytics | Real-time process monitoring, predictive maintenance, informed decision-making |

| Internet of Things (IoT) | Remote monitoring, enhanced connectivity, optimized resource utilization |

As the plastic extrusion world keeps changing, being sustainable and using new tech will be very important to do well and tackle future problems. By leading in these areas, companies can find lasting success in a world that keeps getting harder and busier.

Expert Insights from Plastic Extrusion Professionals

In the world of plastic extrusion, learning from the pros is key. Dr. Chris Rauwendaal, a leading expert, has over fifty years of experience. He is a go-to for advice and guidance.

Rauwendaal has changed the game in plastic extrusion. He’s written over 300 articles and books. His “Polymer Extrusion” book is a must-read for professionals for over 30 years.

Not just an author, Rauwendaal has nine patents, showing his innovation. He’s trained thousands, passing on the best practices. His impact on the industry is deep.

“Continuous learning and collaboration are essential for staying ahead in the plastic extrusion industry. By seeking out expert advice and staying informed about the latest developments, companies can optimize their processes and remain competitive.” – Dr. Chris Rauwendaal

Rauwendaal keeps pushing the industry forward. He’s now collaborating on a project with Giuseppe Poncelli. This project in Italy aims to make big advances soon.

| Accomplishment | Quantity |

|---|---|

| Published papers, books, and video training courses | Over 300 |

| Years of experience in the plastic extrusion industry | 51 |

| Patents held | 9 |

| Individuals trained and educated over four decades | Thousands |

As plastic extrusion keeps growing, staying informed is crucial. Learning from the best, like Dr. Rauwendaal, is a must. With continuous improvement, companies can face the industry’s challenges.

Conclusion

The plastic extrusion industry is growing fast. This growth comes from more people needing plastic, new tech, and a push for green methods. Asia, especially China, will lead this growth. To succeed, companies need to follow market trends, use new technologies, and care for the planet.

Looking to the future, plastic extrusion has a bright road ahead. Companies that keep up with trends and tips will do well. They should use eco-friendly materials and advanced methods like tubing. Doing this will be key for their success.

In short, plastic extrusion is about to expand and change a lot. A focus on new ideas, green ways, and what customers want will set businesses up for the future. To be a leader, companies must keep changing and improving in this exciting field.