The plastic extrusion industry is key in making many different things. It uses a special manufacturing process. This process is vital for creating items like tubes and detailed weather strips. It starts by melting raw thermoplastics or thermosets. Then, the melted material is pushed through a die. This shapes it into a continuous form that cools to become solid. For the best results in plastic extrusion, it’s important to pick the right plastic type, control the temperature, make a good die, and ensure the material flows smoothly through the machine.

When used well, plastic extrusion tech can make high-grade, reliable, and affordable plastic items. It’s very important in the automotive, building, medical, and consumer goods industries. The way extrusion molding works lets producers meet certain needs, proving it’s very flexible. By working on polymer processing techniques like compounding and blown film extrusion, companies can take full advantage of the plastic extrusion industry. This helps keep them ahead in today’s tough market.

At Antecs, we are experts in top-notch plastic manufacturing solutions. We use advanced injection molding and extrusion technologies to make great products for our clients. Our group of skilled engineers and technicians works closely with clients. We learn about their unique needs and offer custom solutions that boost efficiency, quality, and cost savings.

Key Takeaways

- Plastic extrusion is a high-precision manufacturing process used to produce a wide range of products

- Proper selection of materials, temperature control, die design, and uniform flow are critical for effective extrusion

- Plastic extrusion is versatile and adaptable, making it essential in various industries

- Optimizing polymer processing techniques can help companies unlock the full potential of the plastic extrusion industry

- Antecs offers state-of-the-art plastic manufacturing solutions using advanced extrusion technologies

Introduction to the Plastic Extrusion Industry

The plastic extrusion industry is key to innovation and growth in many areas of life. It has changed how we make everything from daily use items to specialized parts. This technology shapes plastic into continuous, even profiles. Because of this, plastic extrusion is a major part of modern manufacturing.

What is Plastic Extrusion?

Plastic extrusion is a way to melt and mold raw plastic into a specific shape. First, tiny pieces of plastic go into a machine called an extruder. There, they are heated until they turn into a thick liquid. This liquid plastic is then pushed through a special hole to make a shape.

This process is known for creating precise and flexible plastic shapes. By adjusting settings like temperature and pressure, manufacturers can make products with certain qualities. These qualities can include being strong, easy to bend, or resistant to chemicals.

Importance of the Plastic Extrusion Industry

The plastic extrusion industry is essential in today’s world for several reasons:

- Versatility: It can make everything from simple tubes to advanced parts. This lets it be used in many fields like building, cars, medicine, and everyday items.

- Efficiency: It can make a lot of the same thing quickly and consistently. This makes it perfect for making things in large numbers.

- Cost-effectiveness: Making long shapes with plastic extrusion is usually cheaper than other ways, like injection molding.

- Material flexibility: It can work with many types of plastic, even recycled ones. This means the best plastic can be chosen for each job, whether it needs to be strong or good for the environment.

This industry is also a big driver of new ideas, pushing technology and design. It allows for things like light car parts and eco-friendly packaging. The plastic extrusion industry always looks for ways to do more.

| Material | Cost | Rigidity | Key Properties |

|---|---|---|---|

| ABS | Medium | High | Impact resistance, toughness |

| PVC | Medium | Varying | Chemical resistance, electrical insulation |

| HDPE | Low | High | Chemical resistance, impact strength |

| Polypropylene | Low | High | Heat stability, chemical resistance |

| Nylon | High | High | Mechanical strength, wear resistance |

There’s a growing need for plastic products in many industries. They are liked for being tough, light, and not rusting. With new ways to use extrusion, more interesting and strong products can be made.

In the end, the plastic extrusion industry is very important for how we make things today. It stands out because it’s versatile, works quickly, and is often cheaper. And it always looks for new and better ways to use plastic. This means it will keep growing and be a big part of manufacturing’s future.

The Plastic Extrusion Process

The plastic extrusion process turns raw polymer materials into various products. These can be any shape or size. It all happens with the help of an extruder. This machine melts and shapes the plastic into what we need.

Key Components of Plastic Extrusion Machinery

The extruder is like the heart of the operation. It has several key parts that work together:

- Hopper: The place where raw plastic is loaded into the machine.

- Barrel: A part with a screw and heaters. It melts the plastic with temperatures between 200-275°C.

- Screw: Driven by a motor, it moves the plastic through the machine. It can create a lot of pressure, above 34 Mpa.

- Die: It helps shape the plastic as it comes out.

- Cooling system: Cools and hardens the plastic after it’s shaped.

Steps Involved in Plastic Extrusion

There are four main steps in plastic extrusion. Each one plays a big role in making the final product right:

- Melting: Plastic is heated until it’s all melted together.

- Pressurizing and shaping: It’s pressed through a die to take its final shape.

- Cooling and solidifying: The shaped plastic is cooled down to keep its shape.

- Cutting or coiling: Then, it’s either cut into pieces or coiled up.

Many types of extrusion can be used, depending on what we need. Tubing extrusion makes tubes and pipes. Blow film extrusion creates thin films, like the plastic in shopping bags.

| Extrusion Process | Product Examples | Key Characteristics |

|---|---|---|

| Tubing Extrusion | Tubes, Pipes | Water-cooling, Precise diameter control |

| Blow Film Extrusion | Shopping bags, Packaging films | Thin, continuous sheeting |

| Sheet Film Extrusion | Thicker plastic sheets | Cooling rolls for thickness control |

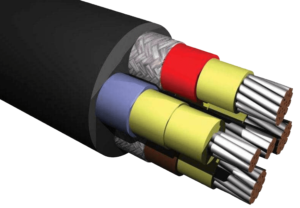

| Over Jacket Extrusion | Wire coatings | Pressure or jacketing tooling |

This method has a lot of benefits. It can make many shapes quickly and at a low cost. It works well with many types of plastic. With the right settings, it can make high-quality products every time.

Types of Plastic Extrusion

Plastic extrusion can make many products in different shapes and sizes. It works by melting plastic and shaping it using a machine. This method is popular because it’s cost-effective. There are many kinds of plastic extrusion for different products.

Film and Sheet Extrusion

Film extrusion makes thin plastic films, used for packaging and bags. These films are under 0.25 millimeters thick. Sheet extrusion, on the other hand, creates thicker plastic sheets. These are over 0.25 millimeters and used in signage and construction.

Tubing and Profile Extrusion

Tubing extrusion is for things like pipes. It needs close control over thickness and size. Profile extrusion makes shapes that aren’t round, for things like window frames. Both processes let companies create specific shapes and sizes.

Blow Film Extrusion

Blow film extrusion is for thin plastic films. It’s used for shopping bags and food packaging. Plastic is blown into a bubble and then cooled to make the film. This process makes a lot of films that are strong and keep things safe.

| Extrusion Type | Typical Products | Key Features |

|---|---|---|

| Film Extrusion | Packaging films, plastic bags | Thin, flexible, less than 0.25 mm thick |

| Sheet Extrusion | Signage, thermoformed parts | Thicker, rigid, above 0.25 mm thick |

| Tubing Extrusion | Pipes, hoses, straws | Hollow, cylindrical, precise wall thickness |

| Profile Extrusion | Window frames, trim, railings | Solid, complex cross-sections, custom shapes |

| Blow Film Extrusion | Shopping bags, food packaging | Thin, flexible, double-layered films |

The plastic extrusion field is always making progress. New tech and materials help make better products cheaper. By knowing the kinds of extrusion available, companies can choose the best for their products. This makes customers happier with what they buy.

Materials Used in Plastic Extrusion

Choosing the right thermoplastic for a plastic extrusion project is key. It makes sure the end product works as it should. Different plastics offer different strengths and resistances. Knowing what the product will go through helps pick the right plastic.

How easily a thermoplastic can be extruded depends on its melting point and other properties. It’s also important to think about the cost and if it follows regulations. Each use needs specific plastic qualities. For instance, outdoor items may need to withstand UV rays. Parts under stress might need to be very strong.

Intek Plastics has over 30 types of thermoplastic for extrusion, like:

- ABS (Acrylonitrile Butadiene Styrene)

- Acrylic

- CPVC (Chlorinated Polyvinyl Chloride)

- Flexible PVC

- Mineral Filled Polypropylene

- Polycarbonate

- Polyethylene

- Polypropylene

- PVC (Polyvinyl Chloride)

- Rigid PVC

- Styrene

- TPA (Thermoplastic Polyamide)

- TPV (Thermoplastic Vulcanizate)

Rigid Polyvinyl Chloride (RPVC) is often used in construction, in places like pipes and profiles. It’s chosen for its firmness, can take a hit, and its UV and fire resistance. Acrylic is picked for its strength and how clearly light shines through it, making it great for use in place of glass.

PVC is known as the third most used plastic in the world. It can be made into RPVC or Flexible PVC, both versatile and liked for their value. Mineral Filled Polypropylene stands out for being stable in heat and cold, and is made in colors or with UV protection.

TPV (Thermoplastic Vulcanizate) has a good mix of strength, flexibility, and survives cold well. It’s a solid choice where toughness is key. ABS is made sturdier than regular polystyrene by nitrile that link the chains, helping it stand up to hits and look shiny.

Styrene combines strength, hardness, and is easy to color. It’s useful in many areas. Polypropylene copolymer balances power, resistance, works in the cold, and can be colored. This makes it fit for various uses.

Picking the right materials for plastic extrusion ensures the product meets standards and performs well. It also considers how easy it is to work with, the cost, and if it’s okay by regulations and for the environment.

Customizing Plastic Extrusion Solutions

At Antecs, we know every customer’s needs are different for custom plastic extrusion. With over 50 years of experience, we can make extrusion solutions fit your needs. Our skilled team will work with you to understand your project, product specifications, and goals. This ensures we create a solution that’s just right for you.

Understanding Customer Requirements

The first step in customizing is understanding what you need. We listen to your goals for the project, the product you want, and how you’ll use it. Based on your info, we choose the best materials, like PVC or TPE, for your product. We also look at things like size accuracy, how strong it is, and if it resists chemicals, so it works well for you.

Designing Custom Dies and Molds

Next, our engineers start to design dies and molds just for you. They think about the material you’ve picked and the final look and size of your product. Our high-tech design tools and 3D printing let us make high-quality dies and molds. This helps us make products that look and work the way you need them to.

Optimizing Extrusion Parameters

We then work to get the best results for your project by fine-tuning the extrusion details. We adjust things like heat, machine speed, and how fast it cools down. We test everything to make sure it’s right, making changes if needed. This makes better, more stable products, reducing problems and improving quality.

| Extrusion Capability | Antecs’ Offering |

|---|---|

| Experience | Over 50 years in custom plastic extrusion |

| Production Facility | 70,000 sq ft state-of-the-art facility |

| Profile Types | Rigid and flexible profiles up to 12m lengths |

| Color Matching | Accurate color matching for low-volume runs |

| Co-Extrusion | Ability to run multiple materials in a single die |

| Prototyping | Complete engineering design services, including 3D print prototypes |

At Antecs, we’re proud to offer custom plastic extrusion that fits your unique needs. Our years of experience, advanced tech, and focus on quality make us a top choice for your extrusion projects.

Optimizing the Plastic Extrusion Process

The process of plastic extrusion is key for top-notch products and high efficiency. Choosing the right material is crucial for things like clarity, toughness, and strength. Each type of plastic brings its own qualities, so picking the best one for each job matters a lot.

Getting the equipment just right is also very important. This means keeping it in good shape and making sure it’s set up correctly. Each plastic needs a certain temperature. Keeping the temperature right means the products will turn out how they’re supposed to.

Next, the design of the die is incredibly important. A well-made die helps shape the plastic correctly the first time, reducing waste and making everything run smoother. The die must be designed with the plastic’s unique traits in mind to get the product’s size and look just right.

To make plastic extrusion as efficient as possible, researchers have looked into what matters for product quality. Narasimha and Rejikumar found that certain settings, like vacuum pressure and speeds, can cause defects if they’re not just right.

| Parameter | Optimization Technique |

|---|---|

| Process Parameters (vacuum pressure, temperature, take-off speed, screw speed) | Taguchi method using Minitab 15 software |

| Parison Swells in Extrusion Blow Molding | 2-20-20 neural network architecture |

| Wire Coating Thickness | Three-layer backpropagation artificial neural network model |

| Flow Rate in Plastic Extrusion Process | Neuro-fuzzy model considering frictional force and extrusion chamber diameter |

| Die Wall Temperature Profiles | Response surface methodology |

| Die Gap Programming for Uniform Part Thickness | Genetic algorithms |

Many ways have been tried to make plastic extrusion better. For instance, Huang and Liao used a special type of computer model to predict how much material was needed in a certain type of plastic shaping. Al Rozuq and Al Robaidi used a different kind of model to measure how thick the coating on wire should be.

Temperature, pressure, speed, and cooling are all very important for the quality of plastic items. It’s key to cool the plastic correctly to avoid it getting deformed or stressed.

To get its best, every part of making plastic items needs to be just so. This goes from the plastic coming in to the product leaving. The way the products are cut and packed is crucial. Storing the products right is also important. If not, they could warp, change color, or even start to break down.

- It’s a must to check the physical and chemical traits of plastics for quality reasons.

- Making plastics by custom methods can make the final products better by meeting the needs of each step.

- Having really good check systems and rules helps keep the plastic making business doing a great job for its customers.

By choosing materials well, fine-tuning equipment, controlling temperatures, designing dies thoughtfully, and using smart optimization methods, makers can boost their work a lot. This means better efficiency and product quality in the end.

Plastic Extrusion Manufacturing Best Practices

In the world of plastic extrusion, sticking to the best practices is key. This ensures the best output and keeps the industry at the top. Companies like Antecs make quality products by checking them closely, maintaining their gear, and training their staff well. This stops mistakes like recalls, rejections, or work stoppages.

Quality Control and Assurance

Keeping an eye on quality is a big part of making plastic products the right way. By having strict checks in place, products stay the same every time, risks of problems go down, and costly mistakes are avoided. Here are some quality control steps:

- Use top-notch materials for the best products

- Keep the walls of products the same thickness all the way through

- Look closely at little details to find the best products

- Check everything at each part of making the product

- Use a system to watch and make the process better

Maintenance and Troubleshooting

Looking after the equipment is very important too. By taking care of machines, businesses can prevent sudden stops and save money. They should regularly clean, check, and adjust their gear. Key tasks include:

- Cleaning and oiling the machines often

- Looking at and changing parts that are worn out

- Adjusting the temperature controls

- Watching how the parts inside the machine are doing to make sure they keep working the same

But, even with good upkeep, things can go wrong. Knowing how to fix problems quickly is crucial. Troubleshooting in plastic making often involves these steps:

| Problem | Possible Causes | Solutions |

|---|---|---|

| Temperature inconsistencies | Faulty heating elements, incorrect temperature settings | Check and replace heating elements, adjust temperature settings |

| Material feeding issues | Clogged feed throat, incorrect material preparation | Clean feed throat, ensure proper material drying and blending |

| Die blockages | Contaminated material, incorrect die design | Purge extruder, review and optimize die design |

| Product defects | Inconsistent wall thickness, poor material quality | Adjust die and process parameters, use high-quality materials |

Putting quality, maintenance, and quick fixes first helps plastic makers run better. They cut waste and make top-notch products every time for their customers. Antecs sets a great example in the plastic making world by following these rules. Their top products meet the toughest standards.

Innovations in Plastic Extrusion Technology

In recent years, the plastic extrusion industry has seen big improvements thanks to new technologies. These changes have made making plastic products faster, better, and more versatile for many industries.

Advanced Extrusion Techniques

Techniques like co-extrusion and multi-layer extrusion have brought new ways to make advanced plastic products. Co-extrusion makes it possible to use multiple polymers at once, creating layers with different functions. This means products can have better barriers, more strength, and look nicer.

Multi-layer extrusion lets manufacturers stack several materials. This creates products that excel in performance, from better barriers to durability and added functions.

| Technique | Benefits | Applications |

|---|---|---|

| Co-extrusion | Improved layer adhesion, better barrier properties, product consistency | Food packaging, medical devices, automotive components |

| Multi-layer extrusion | Enhanced barrier properties, strength, aesthetics | Packaging films, tubing, wire and cable insulation |

Smart Extrusion Systems

Now, we have smart extrusion systems thanks to Industry 4.0. These systems use sensors and data analytics to adjust the manufacturing process in real time. This makes sure product quality stays high and waste stays low.

These smart systems bring tons of benefits:

- Real-time process monitoring and control

- Predictive maintenance capabilities

- Reduced downtime and increased productivity

- Improved product quality and consistency

- Enhanced energy efficiency and reduced waste

As time goes on, these smart systems will become very common, leading to even better efficiency, quality, and sustainability in the plastic extrusion industry.

“The integration of smart manufacturing technologies is transforming the plastic extrusion industry, enabling more automation, data-driven decision making, and real-time process optimization.”

The future of plastic extrusion is very exciting. We can expect to see more eco-friendly materials, lighter materials for planes and cars, and a big push for sustainability. With these new developments, the plastic extrusion industry is headed for growth and success.

Applications of Extruded Plastic Products

Extruded plastic products are handy across many fields. They are widely used in industries like packaging, construction, building, and automotive. For over 100 years, plastic extrusion has been a key technology. It’s the go-to for making large amounts of plastic items. This includes daily use and thermoplastic items.

Packaging Industry

For packaging, extruded plastics make items like films, bags, and bottles. They have great barrier properties and last long. This makes them perfect for food, goods, and medicine. High and low-density polyethylene, polypropylene, and PVC are common in this sector.

Construction and Building Materials

The construction field uses plastic profiles for many things. This includes window frames and deck railings. These materials need little care and resist weather and rust. They are vital in construction for their durability.

Automotive Components

In cars, extruded plastics are for interiors and exteriors. They make dashboards, bumpers, and more. These parts help make vehicles lighter, more fuel-efficient, and stylish. Materials like polypropylene and noryl are common.

“Plastic extrusion is utilized by companies ranging from window manufacturers to adhesives producers, catering to startup ventures seeking prototypes and established companies seeking cost-cutting solutions.” – Antecs

| Industry | Extruded Plastic Applications |

|---|---|

| Packaging | Flexible packaging films, bags, rigid containers, bottles |

| Construction | Window frames, door panels, siding, decking, deck railings, wire insulation, weather stripping |

| Automotive | Dashboards, door panels, bumpers, trim parts |

Sustainability in the Plastic Extrusion Industry

The plastic extrusion industry is turning towards sustainability. It’s focusing on being eco-friendly. This includes using recycled plastics and reducing waste.

They are also changing the way they make things. Now, they use materials that are better for the planet. For example, they grind up used plastic and use it again.

This reduces how much new plastic they need. It’s a big step in saving the earth. It helps keep plastics out of our oceans and from polluting the land.

By finding new ways to use plastic, companies are being very smart. They make sure nothing goes to waste. For instance, Plastic Extrusion Technologies (P.E.T.) uses everything it starts with.

Many companies are working together to make things better. They share ideas to use less energy and make products that are kind to our planet. Doing this can change the whole industry for the better.

Working with recycling plants is another good move. It means they can find new plastic to use without making more. This step is really good for the earth. It makes sure we use less and keep recycling materials.

Companies are also looking at 3D printing to make different products. These products are easy to recycle. It’s all about using less and doing more for the earth. This is a big change in making things.

“Sustainability is an imperative piece of modern life in the plastic extrusion industry, benefiting the environment, employee morale, and overall quality of production processes.”

There’s a new way to recycle plastics that weren’t recyclable before. Condale Plastics is working on it with other companies. This way, they can turn very hard-to-recycle plastics back into useful materials.

- Purification: Dissolving plastics in solvents for high-quality polymer extraction from mixed waste streams.

- Depolymerisation: Breaking down polymers like PET into monomeric forms for repurposing.

- Feedstock recycling: Methods like pyrolysis, gasification, and hydrothermal treatment transform polymers into reusable components.

This new recycling method is very important for our planet. It changes how we see waste. Now, we see it as something we can use again. This is great for the businesses that do the recycling too. It’s a win-win for everyone.

| Sustainable Practice | Impact |

|---|---|

| Recycled Plastic Usage | Reduces reliance on virgin plastic and contributes to sustainability efforts |

| Waste Reduction | Prevents plastic waste from reaching landfills and supports environmental conservation |

| Chemical Recycling | Repurposes materials previously deemed non-recyclable and promotes a circular economy |

This new way of recycling plastics is changing the industry. It’s making everything better for the earth. With these smart ways, the plastic industry is moving towards a greener future.

Challenges and Opportunities in the Plastic Extrusion Industry

The plastic extrusion industry is at a turning point, facing challenges and chances as it changes. Its main tasks include tackling environmental concerns and keeping up with technological advancements. This means manufacturers need to change to stay on top and please their customers.

Addressing Environmental Concerns

The plastic extrusion industry is under pressure to deal with plastic waste’s impact on the environment. Manufacturers must find ways to make their practices and products eco-friendlier. This involves creating materials that break down naturally or can be recycled, becoming more efficient to save energy and reduce waste, and working with others in the industry to promote reusing materials.

Recent studies show that people want more sustainable plastic products. Big names in the industry are working hard to create new materials and ways of making things that cause less harm. They’re using more recycled plastics too. For instance, companies like Plastic Extrusion Technologies are making products with recycled plastic.

Embracing Industry 4.0 Technologies

While it’s challenging to address environmental worries, new technologies offer great opportunities. By using smart sensors, data analytics, and automated systems, manufacturers can get better at what they do. They can make their process faster, cheaper, and produce higher-quality products. These technologies let them watch the production closely and fix problems fast to avoid waste and delays.

| Technology | Benefits |

|---|---|

| Advanced Sensors | Real-time monitoring of extrusion parameters, enabling quick adjustments and improved quality control. |

| Data Analytics | Insights into production efficiency, material usage, and equipment performance, facilitating data-driven decision making. |

| Automation Systems | Streamlined operations, reduced labor costs, and improved consistency in product quality. |

These new technologies also help with predictive maintenance. This means manufacturers can fix their equipment before it breaks, saving time and money. And better connections with suppliers and customers mean the whole chain works better. It makes everything more efficient and competitive.

“The plastic extrusion industry is poised for growth as it embraces sustainable practices and Industry 4.0 technologies. By investing in innovation and collaboration, manufacturers can overcome challenges and seize opportunities to drive the industry forward.” – Industry Expert

To keep up with these changes, companies should focus on being sustainable and using new technology. They need to be innovative. If they find eco-friendly ways to make their products, work more efficiently, and use data and automation, they can do well. They will not only please their customers but also help the industry become better for the environment.

Choosing the Right Plastic Extrusion Partner

Selecting a trusted plastic extrusion partner is key for your project’s success. It’s vital to look into their extrusion abilities, quality standards, certifications, and technical knowledge. A strong candidate, like Emco Industrial Plastics, brings over thirty years of experience to the table.

Evaluating Extrusion Capabilities

A quality extrusion partner should work in a top-notch facility with advanced tools. Emco Industrial Plastics functions from a large site, furnished with the latest equipment. They provide a wide range of services, from molding to custom fabrication.

This company stands out for its ability to work with various materials. They are proficient in handling everything from ABS to PETGs. This broad range of materials can meet the needs of many industries.

Assessing Quality Standards and Certifications

When picking a plastic extrusion partner, quality and certifications are important. Seek out companies with recognized quality management and relevant product certifications. These show dedication to high-quality, reliable outcomes.

Technical know-how is equally essential. Emco Industrial Plastics uses CNC machining and provides injection molding. They offer a full cycle of services, from design to shipping.

Good customer support makes a big difference too. Emco places a high value on clear communication and meeting deadlines. This is crucial for a successful project.

| Consideration | Importance |

|---|---|

| Cost-effectiveness | Ensuring the project remains within budget while maintaining quality |

| Specific characteristics needed | Choosing materials that meet the required properties for the application |

| Availability of materials | Ensuring a consistent supply of the chosen materials for uninterrupted production |

| Appearance | Selecting materials that provide the desired aesthetic appeal |

| Durability and strength | Opting for materials that can withstand the intended use and environment |

| Environmental and thermal characteristics | Considering the material’s performance in specific environmental and temperature conditions |

By wisely considering these aspects and picking a top-notch partner like Emco Industrial Plastics, your project can thrive. You’ll gain from their expertise, capabilities, and dedication to quality.

Conclusion

The plastic extrusion industry is moving forward fast. Technology, green efforts, and changing needs are pushing its growth. Companies like Antecs are using the latest tech and earth-friendly materials. This allows them to make top-notch, unique products for many areas.

This trend will keep going. Companies must use advanced tech and green methods to stay ahead. By doing so, they can meet the increasing needs of the plastic extrusion market. Antecs, for example, has a wide range of services for different clients. They have a top certification and aim for the best in their work.

Being up-to-date with tech and caring for the planet is key for the industry. It’s creating a better future while being creative. Things like eco materials and combining 3D printing with plastic extrusion show the way forward. The plastic market is growing, offering a lot of chances for those in the plastic extrusion world.