Antecs Plastic Recycling Machine

Antecs Plastic Recycling Machine Recommendation

Let's take you on an all-round journey to understand the most advanced plastic recycling machine in 2024. It will bring you a different and exciting experience.

Buy high quality recycled plastic extrusion machine

Antecs Plastic Recycling Machine Features

Plastic recycling machine come in various types and sizes, each designed to handle different types of plastic waste and recycling processes.

Material Handling System

Includes conveyors, hoppers, and sorting mechanisms to handle and sort incoming plastic waste based on type, color, and quality.

Shredding Unit

Equipped with sharp blades to shred the plastic waste into smaller pieces, making it easier to process further.

Washing Unit

Cleans the shredded plastic by removing contaminants like dirt, labels, and residues using water and sometimes detergents.

Drying Unit

Dries the washed plastic flakes to remove excess moisture using centrifugal dryers or hot air blowers.

Melting Unit

When you melt the cleaned and dried plastic flakes, they turn into melted plastic. Then, you can shape this melted plastic into new products through extrusion or molding.

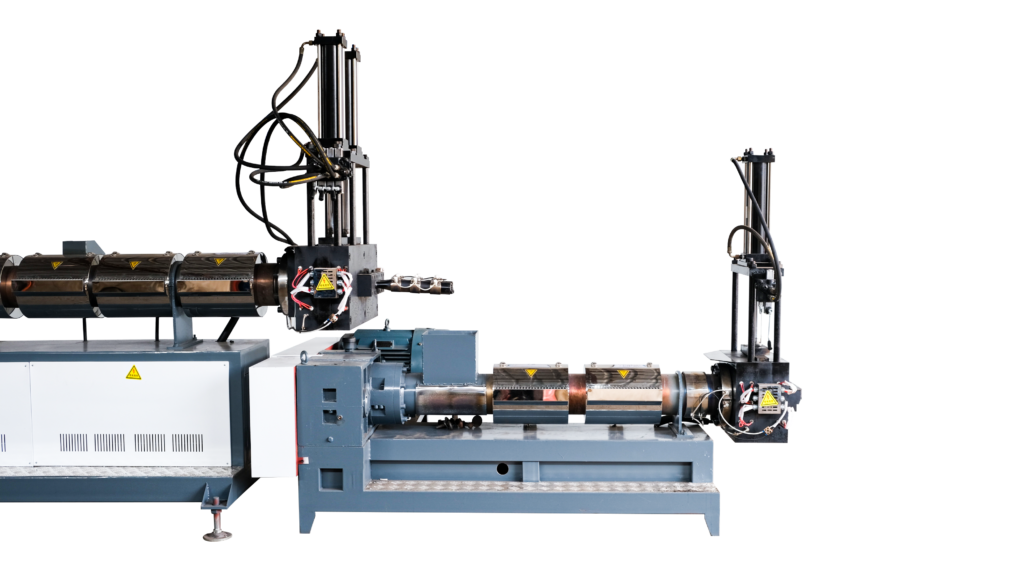

Extrusion Unit

If factories want to use the recycled plastic to make things like plastic sheets, pipes, or shapes, they might use a process called extrusion. In this process, they shape the melted plastic into the needed form.

Antecs plastics machinery manufacturer for 19 years

Founded in 2005, Antecs Plastics Machinery is a manufacturer of advanced plastics recycling equipment. We provide equipment for the recycling of large quantities of plastic waste from consumers, businesses and industry.

Our team of engineers and technicians work hard to create new and better machines. They focus on efficiency, ease of use, durability, and safety. You can trust that our equipment is made with the best materials and parts. If you take care of it, it will work well for many years. Because we always strive to be the best and make our customers happy, Antecs Recycling Machinery is known all over the world as one of the top makers of recycling machines.

For plastic recycling plants that need everything in one package, we provide full design and installation of recycling lines. This includes lines for washing PET bottles, washing PE film, and even whole plants for treating municipal waste (Material Recovery Facilities, MRF). With more than twenty years of experience in plastic recycling and a long list of successful projects, we believe we can help your recycling plant grow quickly and efficiently.

Play Video about Plastic Recycling Machine

Disclaimer: Antecs belongs to the sub-brand of JianTai, established to serve high-end clients.

Why Choose A Plastic Recycling Machine From Antecs?

Advantages of Antecs' plastic recycling machines

Innovative Technology

Antecs machines can be fitted with advanced technology. Consequently, different kinds of plastics are processed efficiently. As a result, this leads to better quality recycled materials.

Durability and Reliability

Antecs machines could be equipped with advanced technology. Because of this, the machines ensure efficient processing of various types of plastics. As a result, this leads to higher quality recycled materials.

Customization

Antecs might offer customizable solutions that can be tailored to specific recycling needs. For example, whether for small-scale recycling facilities or large industrial operations, these solutions are both flexible and effective. As a result, they can help meet the needs of different types of recycling projects.

Energy Efficiency

Their machines could be designed to use less energy than others. This not only saves money on running them but also fits with sustainable practices. As a result, these machines are both cost-effective and environmentally friendly. Furthermore, using less energy means they help protect the planet.

Support and Service

Choosing Antecs could mean access to excellent customer support. This includes installation, training, and after-sales services. Consequently, this ensures that the recycling process runs smoothly. Furthermore, having great support helps solve any problems quickly.

Environmental Impact

By focusing on recycling machinery, Antecs contributes to environmental sustainability. This helps businesses reduce their carbon footprint and waste production. As a result, Antecs plays a big role in protecting the planet.

Cost-Effectiveness

As time goes on, the efficiency and durability of their machines could lead to cost savings. Consequently, this makes them a smart financial choice. Additionally, saving money over time helps businesses grow and succeed.

Compliance with Regulations

Antecs machines might be designed to meet current environmental and safety regulations. This is crucial because it helps businesses avoid fines and legal issues. Furthermore, following these rules protects both the environment and the workers. As a result, companies can operate smoothly and responsibly.

Special features of Antecs plastic recycling machines

Customization and Versatility

One great thing about Antecs recycling machines is how customizable they are. These machines can be adapted to handle various types of plastic materials. For example, they can process different plastics like PET and HDPE. Additionally, they can manage more challenging plastics like PVC and ABS. This flexibility supports businesses in recycling many types of plastics. As a result, companies can expand their recycling capabilities without needing to invest in multiple machines. This versatility is crucial for companies that want to grow and recycle more efficiently.

Enhanced Durability with Military-Grade Components

Antecs machines are built with military-grade components. This ensures long-lasting durability and robustness, even under the harsh conditions of a recycling facility. Because of this, the machines need fewer replacements and repairs. As a result, businesses can enjoy long-term savings and reliability. Additionally, the strong components help the machines perform well for many years.

What Materials Are Suitable For Plastic Pelletizing?

HDPE (High-Density Polyethylene) Pelletizing

LDPE (Low-Density Polyethylene) Pelletizing

PP (Polypropylene) Pelletizing

PE (Polyethylene) Pelletizing

ABS (Acrylonitrile Butadiene Styrene) Pelletizing

PA (Polyamide) Pelletizing

HIPS (High-mpact Polystyrene) Pelletizing

The Plastic Pelletizing Process with Antecs Recycling Machines

At Antecs, we design our plastic recycling machines to efficiently transform waste plastics into high-quality pellets. First, we begin the process by collecting and sorting various plastic materials. Once sorted, we thoroughly clean the plastics to remove any contaminants.

Next, we feed the cleaned plastics into the hopper of the Antecs pelletizing machine. This machine features a robust single-screw extruder that heats and melts the plastic materials. Then, the extruder pushes the melted plastic through a die, shaping it into thin strands.

After that, we immediately cool these strands in a stainless steel water tank to solidify them. Following the cooling process, an integrated pelletizer cuts the strands into uniform pellets. We then air-dry the resulting plastic pellets to remove any residual moisture.

Throughout the process, the machine's PLC touchscreen control ensures precise operation. Additionally, we use high-quality components like Delixi electrical parts and stainless steel heating bands to guarantee durability and efficiency. Consequently, we produce final plastic pellets that are ready for use in manufacturing new plastic products, promoting sustainability and reducing environmental impact.

In conclusion, Antecs provides innovative recycling solutions that contribute to a circular economy and a greener future.

Improving the efficiency of plastic recycling machines

Technological Upgrades: Adopting advanced recycling technologies and equipment, such as automated control systems, efficient sorting techniques, and high-pressure, high-temperature processing methods, can enhance recycling efficiency.

Material Selection: Choosing high-quality plastic materials suitable for recycling and employing advanced sorting and processing techniques can improve the quality and utilization rate of recycled plastics.

Process Optimization: Optimizing the recycling process, including reducing energy consumption, streamlining operational workflows, and maximizing equipment utilization, can effectively boost machine efficiency.

Training and Skill Enhancement: Providing training for employees to improve their skills in operating and maintaining recycling machines ensures that the machines operate at optimal performance.

Maintenance and Care: Performing regular maintenance and care for the machines, checking equipment status, preventing potential failures, and extending machine lifespan.

Environmental Considerations: Addressing environmental impacts of the recycling process, such as reducing emissions, controlling noise, and treating wastewater, aligns with environmental regulations and enhances machine sustainability.

Data Analysis and Monitoring: Utilizing data analytics and monitoring systems to track machine performance and operational metrics in real-time helps identify issues promptly and take corrective actions to improve efficiency and accuracy.

Other Plastic Recycling Machine Types

Antecs Machinery

You're one step away from success!

Let's have a chat

Comprehensive Guide to Plastic Recycling Machines

Introduction

Plastic recycling machines are very important. They help turn old plastic into new products. This guide will explain how these machines work. We will also talk about the different types of plastic recycling machines.

What Are Plastic Recycling Machines?

Plastic recycling machines are machines that change old plastic into new things. They do this by breaking down the plastic and making it into small pieces. These small pieces can then be melted and used to make new plastic products.

Why Is Plastic Recycling Important?

Plastic recycling is important for many reasons. First, it helps keep our environment clean. When we recycle plastic, we use less energy and save natural resources. This means there is less pollution and waste.

Types of Plastic Recycling Machines

There are different types of plastic recycling machines. Each type has a special job. Here are some common types:

-

Shredders

- Shredders cut big pieces of plastic into small pieces.

- They are the first step in the recycling process.

-

Granulators

- Granulators make the small pieces even smaller.

- They are very strong and can handle tough plastic.

-

Extruders

- Extruders melt the small plastic pieces.

- They turn the melted plastic into long, thin shapes.

-

Pelletizers

- Pelletizers cut the long, thin shapes into small pellets.

- These pellets can be used to make new plastic products.

How Do Plastic Recycling Machines Work?

Plastic recycling machines work in a few steps. Here is a simple way to understand the process:

-

Collecting Plastic

- First, old plastic is collected from homes, businesses, and other places.

- This plastic is then taken to a recycling center.

-

Sorting Plastic

- At the recycling center, the plastic is sorted by type and color.

- Different types of plastic need different machines.

-

Cleaning Plastic

- The sorted plastic is cleaned to remove dirt and other things.

- This step is important to make sure the new plastic is high quality.

-

Shredding Plastic

- The cleaned plastic is put into a shredder.

- The shredder cuts the plastic into small pieces.

-

Granulating Plastic

- The small pieces go into a granulator.

- The granulator makes the pieces even smaller.

-

Melting Plastic

- The small pieces are melted in an extruder.

- The melted plastic is shaped into long, thin strands.

-

Making Pellets

- The long strands are cut into small pellets by a pelletizer.

- These pellets are ready to be made into new products.

Benefits of Using Plastic Recycling Machines

There are many benefits to using plastic recycling machines. Some of them are:

-

Saving Resources

- Recycling plastic saves natural resources like oil and gas.

- This helps protect the environment.

-

Reducing Pollution

- Recycling plastic reduces pollution.

- Less plastic waste means cleaner air and water.

-

Creating Jobs

- Recycling centers and factories need workers.

- This creates jobs and helps the economy.

-

Saving Energy

- Recycling plastic uses less energy than making new plastic.

- This helps save energy and reduce greenhouse gases.

Conclusion

Plastic recycling machines are very important. They help turn old plastic into new products. By using these machines, we can save resources, reduce pollution, create jobs, and save energy. Understanding how these machines work helps us see why recycling is so important. Let’s all do our part to recycle and keep our planet clean!