Antecs is a top provider of plastic extrusion equipment. They offer a wide range of machines for different needs. With their experienced team and many used extruders from top brands, Antecs is your go-to for plastic extrusion equipment deals.

If you need pelletizing, sheet, film, or pipe extruders, Antecs has what you’re looking for. Their selection includes items from well-known brands like American Leistritz and Milacron. You can also find compounding and profile extrusion equipment.

Antecs knows how critical it is to choose the right equipment for your job and budget. Their polymer processing experts will help you find the best solutions. They offer great deals on used extruders, aiding companies in improving their process without high costs.

Plastic extrusion is a method used to shape melted plastic into various products. This includes items like pipes, fencing, and window frames. With Antecs’ equipment, manufacturers can boost their production and get top-notch results.

Key Takeaways:

- Antecs offers a wide selection of plastic extrusion equipment from top brands

- Their team of specialists helps customers find the best equipment for their specific needs

- Antecs provides competitive prices on high-quality used extruders

- Plastic extrusion is a versatile manufacturing process used to produce various products

- Antecs’ solutions help manufacturers optimize production and achieve cost-efficiency

Introduction to Plastic Extrusion Equipment

Plastic extrusion equipment is key in making different items for many industries. It can make plastic profiles, tubes, sheets, and films without stopping. For companies, it is a must-have for making their goods efficiently.

What is Plastic Extrusion?

Plastic extrusion turns plastic into a continuous shape. First, plastic pellets are melted in an extruder. Then, the hot plastic is pushed through a die. This makes products like sheets or tubes with the same quality each time.

Importance of Plastic Extrusion in Various Industries

Plastic extrusion is used in many fields, such as:

- Automotive: Interior trim and under-the-hood parts

- Food and beverage: Packaging materials and dispensing tubes

- Construction: Window frames and decking

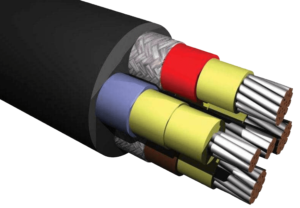

- Electronics: Wire coating and electronic housings

Its flexibility lets companies make items that meet their needs. By choosing the right plastic materials, items can be strong, flexible, or resistant to heat.

| Material | Application |

|---|---|

| PVC | Pipes, window profiles, wire insulation |

| HDPE | Bottles, containers, pipes |

| PP | Packaging, automotive components |

| ABS | Electronic housings, automotive interior parts |

Having the right plastic extrusion equipment helps businesses work better. Antecs sells top-quality used machines. They make sure companies get the equipment they need to succeed.

Types of Plastic Extrusion Machines

There are various types of plastic extrusion machines, each meeting unique manufacturing needs. The market for these machines was worth over $6 million in 2019. It’s projected to hit nearly $8 million by 2027, with a growth rate of 4.5 percent. Antecs provides a wide selection of used extruders and extrusion lines from leading brands. This helps fulfill the plastic extrusion industry’s diverse needs.

Single Screw Extruders

Single screw extruders are widely used in the plastic industry. They have a single screw that rotates within a barrel. This process melts, mixes, and pressurizes the plastic material. The material is then pushed through a die to form the needed shape. Single screw extruders are best for thermoplastics. They can make several tons of plastic per hour, even if the machine is not large.

Twin Screw Extruders

Twin screw extruders have two screws that spin together inside a barrel. They are more versatile than single screw extruders. This is because they offer various screw sizes and configurations to fit different industries. Twin screw extruders are great at mixing materials. They work well for blending materials with additives or fillers. With twin screw extruders, you can mix two additives more effectively because of features like kneading blocks.

| Extruder Type | Key Features | Applications |

|---|---|---|

| Single Screw | One screw, simple design, high output | Thermoplastics, high-volume production |

| Twin Screw | Two screws, better mixing, versatility | Compounding, materials with additives/fillers |

Sheet and Film Extruders

Sheet and film extruders make flat plastic sheets or films. They can be different thicknesses and widths. These machines use special parts like die lips, chill rolls, and winding systems. These ensure the plastic is of even thickness and has a smooth surface. Sheet extrusion is used for signs, packaging, and thermoforming sheets. Film extrusion helps make bags, wraps, and agricultural films.

Keeping the right temperature is key for all plastic extrusion machines. Different kinds of plastics need specific extrusion screw designs. This includes the screw’s length, diameter, pitch, and angles. The latest in extrusion screw design is always improving. It meets more specific needs and boosts efficiency.

Applications of Plastic Extrusion Equipment

Plastic extrusion equipment is key in many areas, making products we see daily. It helps make things from car parts to building materials. It’s also vital for packaging, medical devices, and many consumer goods.

In cars, it makes inside trim, outer moldings, and parts under the hood. These parts add style, function, and safety. In building, it makes window frames, doors, and more, known for their strength and upkeep.

For packaging, it creates plastic films, sheets, and containers, keeping goods safe. In healthcare, it makes items like catheters. They must meet strict safety standards.

For consumer goods, it’s behind everything from household items to toys. Its flexibility in shaping colors and sizes caters to many tastes. This makes it very versatile.

Plastic extrusion can create many things like tubing, sheets, weather stripping, and more.

It works with several thermoplastics:

- Polystyrene

- PVC

- Nylon

- Polyethylene (low and high-density)

- Polypropylene

- Acrylic

- Polycarbonate

- ABS

- TPR

Antecs sells used extrusion gear from top brands. This lets businesses find what they need. It offers custom options, special color mixes, and handles big orders. Extrusion is essential in today’s manufacturing.

Key Features to Consider When Choosing Plastic Extrusion Equipment

Selecting the right plastic extrusion equipment is crucial for your production’s success. The Antecs team can help you find the best fit for your needs and budget. Let’s dive into the important factors to keep in mind.

Extrusion Capacity

Extrusion capacity is vital, affecting how quickly you can produce items. This rate must match your production needs. While high-speed extruders make more, they can also use a lot of energy. They often need a more powerful motor and other parts that use a lot of energy too.

Screw Design

The screw design is key for mixing materials well. The right design is crucial for your product quality. Twin screw extruders work best for making PVC pipes. They mix PVC powder evenly without harm. On the flip side, single screw extruders are great for PE pipe making.

Heating and Cooling Systems

Good heating and cooling keep your materials at the right temperature. Heating uses a lot of power to start, but then the motor keeps things hot for melting. Smart systems help ensure everything stays at the perfect temperature. This is really important for high-quality output and the extruder’s own performance.

| Component | Importance |

|---|---|

| Barrel Temperature | Critical for finished product quality; slight temperature differences can cause flaws |

| Die Construction | Uneven flow can lead to uneven product formation, stress points, and warping during cooling |

| Cooling Process | Incorrect cooling after initial profile creation can result in tube collapse and affect product quality and safety |

Control and Monitoring Systems

Good control systems help you manage the whole production better. They also make production more efficient. Modern equipment lets you control the whole line from one place, thanks to smart technology. Using quality parts from brands like Siemens makes a big difference in performance.

Make sure the equipment can handle vibrations well. This helps it last longer and work better.

With Antecs’ support and by focusing on these features, you can make a great choice. This will improve your production and the quality of your products.

Top Brands in the Plastic Extrusion Industry

The plastic extrusion industry boasts many top brands. They’re known for making excellent extrusion equipment. These companies always aim for innovation, reliability, and making customers happy. Antecs is a reliable place for buying used plastic extrusion equipment. They keep many machines from those top brands in stock. This means you can get the newest technology at a good price.

Davis-Standard

Davis-Standard is a world leader in making extrusion and converting technology. They have over 14 types of products that help many industries. Davis-Standard’s extruders last a long time. Some have been in use for 50 years. They offer single screw extruders, twin screw extruders, and special lines for pipes, profiles, sheets, and films.

Battenfeld-Cincinnati

Battenfeld-Cincinnati is famous for its new ideas in making pipes, profiles, and sheets. They make modern extrusion lines that make high-quality products efficiently. Battenfeld-Cincinnati has a big selection, including single and twin screw extruders. They also make whole extrusion systems for different needs. They are all about using new technology and being eco-friendly.

Milacron

Milacron is at the front of making advanced extrusion technology for plastic. Their machines are known for being precise, reliable, and for their many uses. They offer a big range of extrusion solutions, like single and twin screw extruders. They also have special systems for making pipes, profiles, and more. Milacron always keeps working on new technology to make better quality products and be more efficient.

KraussMaffei Berstorff

KraussMaffei Berstorff makes top-notch extrusion systems for pipes, profiles, and sheets. Their modern extrusion equipment meets the needs of industries like construction, cars, and packaging. They have single and twin screw extruders, and complete lines for specific jobs. With a focus on quality, new ideas, and helping customers, KraussMaffei Berstorff is a respected name in the plastic extrusion world.

| Brand | Experience | Specialization |

|---|---|---|

| Davis-Standard | Over 50 years | Single screw extruders, twin screw extruders, pipe, profile, sheet, and film extrusion lines |

| Battenfeld-Cincinnati | Decades of innovation | Pipe, profile, and sheet extrusion solutions |

| Milacron | Long-standing industry presence | Single screw extruders, twin screw extruders, pipe, profile, sheet, and film systems |

| KraussMaffei Berstorff | Extensive industry experience | Extrusion systems for pipes, profiles, and sheets |

By working with Antecs, you can get amazing extrusion equipment from the top brands at good prices. Antecs’ skilled team picks and looks after a big variety of used machines. This means customers can find the right equipment for their needs and budget.

Plastic Extrusion Equipment for Specific Applications

Plastic extrusion equipment is made for certain needs. This helps it work well and make quality products. Antecs has a big selection of used machines. They are made to fit many industries’ specific needs, helping customers choose the right gear.

Pipe and Tubing Extrusion Lines

These are tools to create plastic pipes, tubes, and more. They are used in plumbing, electric work, and medical fields. The machines work with different plastic types like PVC and HDPE. This creates products that all look the same and have the same quality. Antecs has top-quality used machines from leading brands, ensuring they last.

Profile Extrusion Systems

Profile machines make special shapes for building, cars, and more. They craft items like window frames and car parts. Antecs has a range of quality used machines. This means they offer accuracy and flexibility for many jobs.

Sheet and Film Extrusion Equipment

These make plastic sheets and films for various uses. You see them in wrapping, signs, and farming. They make materials that are equally thick and clear. Antecs offers different second-hand lines, making it easy to get what you need within budget.

| Extrusion Equipment | Applications | Key Features |

|---|---|---|

| Pipe and Tubing Extrusion Lines | Plumbing, electrical conduits, medical devices | Consistent dimensions, material compatibility |

| Profile Extrusion Systems | Construction, automotive, industrial components | Complex cross-sections, precision, versatility |

| Sheet and Film Extrusion Equipment | Packaging, signage, agricultural applications | Consistent thickness, clarity, mechanical properties |

“Antecs’ extensive inventory of used plastic extrusion equipment, tailored to specific applications, enables customers to find the perfect machine for their unique requirements and budget.”

Antecs has a wide variety of used extrusion machinery, perfect for different tasks. This allows customers to make their production better. They can also improve the quality of their items and work more efficiently.

Advantages of Investing in High-Quality Plastic Extrusion Equipment

Choosing top-tier extrusion equipment has many upsides for makers aiming to better their productions. This approach leads to top-notch efficiency and product similarity. With less downtime and maintenance expenses, businesses soar.

Top-notch extrusion gear guarantees top-level performance and trustworthiness. They boast high-tech parts and systems for better control and optimization. This betters product quality, whether for cars or medical tools.

The headlining advantage is better speed in making products. These gadgets work materials quickly and at the ideal heat, making output times zip by. For instance, dual-screw extruders outdo single-screw ones in speed, perfect for large runs.

The automation and precision of plastic extrusion lines lead to consistent and precise production of plastic components, ensuring that products meet the required specifications and quality standards.

Equipment of this grade means less time off. With tough parts and solid operation, they’re ready for non-stop use. This means fewer faults and stops, helping makers keep customers happy with steady goods.

These top-line machines also breathe easier in the maintenance department. Their sturdy build and features cut down on upkeep, saving both on repairs and the time it takes. Keeping them running well is more straightforward too, lightening the load on maintenance staff.

| Advantage | Description |

|---|---|

| Improved Production Efficiency | High-quality extrusion equipment enables faster output rates and reduced cycle times, optimizing production processes. |

| Increased Product Consistency | Advanced control systems and precision components ensure consistent product quality across various applications. |

| Reduced Downtime | Durable construction and reliable performance minimize breakdowns and interruptions in production. |

| Lower Maintenance Costs | Robust design and advanced features reduce the need for frequent maintenance and repairs, saving costs over time. |

Investing in elite extrusion gear is a game-changer for brands like Antecs. Their gear leads to better process speeds, quality, and dependability. And this, in turn, boosts profits and secures long-run triumph.

Cost Considerations for Plastic Extrusion Equipment

When you buy plastic extrusion equipment, you must look at all the costs. This includes the price to start, run, and fix the machines. By thinking about these costs, companies can use their money well. They can get top-notch equipment that fits their needs.

Initial Investment

Getting started with plastic extrusion equipment costs a lot. Simple machines are priced from a few to several thousand dollars. More advanced machines range from tens to hundreds of thousands. Special machines can cost even more. The price changes depending on what kind of machine, how big it is, and what it does. Antecs sells used machines at good prices. This helps companies save money on their first investment.

Operating Costs

It’s also key to look at how much it costs to keep the extrusion equipment running. This includes what you spend on energy, materials, and workers. The kind of plastic you use and the machine’s design affect these costs. The size of the machine and its output every hour change how much you spend. Picking machines that use less energy and work well saves you money.

Maintenance and Repair Expenses

Keeping plastic extrusion equipment in top shape takes regular care. This includes checkups, cleaning, and fixing parts that wear out. If you don’t take care of your machines, they break more often. This can stop your work and cost you money. So, it’s smart to think about these long-term costs. Antecs is here to help with advice on keeping machines healthy. They provide support after you buy, which cuts down on these costs.

| Plastic Extruder Type | Price Range |

|---|---|

| Entry-level | Thousands to tens of thousands of dollars |

| Medium-capacity | Tens to hundreds of thousands of dollars |

| Premium custom | Hundreds of thousands of dollars or more |

Picking the right plastic extrusion equipment means thinking about several things:

- What kind of machine, how big, what it can do, and how it can be changed

- The machine’s energy use and its needs for different plastics

- That you get help and advice after buying from the company

- Comparing prices and what you get for your money

- Planning for costs beyond just buying the machine, like shipping and setup

- Figuring out how much you need to make and then choosing the machine that fits this

By really looking at all the costs and choosing a great supplier like Antecs, companies can wisely invest in plastic extrusion equipment. This boosts their production and helps them succeed in the long run.

Factors Affecting the Price of Plastic Extrusion Equipment

Thinking about buying plastic extrusion equipment? It’s key to know what factors affect its price. The size of the machine and how much it can produce are major ones. Bigger and higher-output machines usually cost more. The brand’s good name and the level of its technology also make a difference. Often, you pay more for top brands and the latest tech.

If you need something specific, like a special screw design or a unique control system, the price will go up. These special features can make your machine work better for your specific needs. But, they do bump up the cost.

Deciding between new or used equipment? Used machinery is cheaper, but you must think about its condition. If it’s very worn or needs lots of fixing, that affects the price.

| Factor | Impact on Price |

|---|---|

| Machine Size | Larger machines generally cost more |

| Production Capacity | Higher-output machines command higher prices |

| Brand Reputation | Top-tier brands often come at a premium |

| Technology Level | Advanced features and capabilities increase cost |

| Customization | Specialized designs and systems add to the price |

| Used Equipment Condition | Wear, tear, and necessary upgrades affect pricing |

Antecs knows a lot about pricing used plastic extrusion equipment. They look at things like machine size, how much it can produce, brand name, tech level, custom features, and its condition. This helps ensure buyers get fair prices.

Our goal is to provide high-quality extrusion equipment at competitive prices, helping businesses optimize their production processes and achieve their goals.

Antecs is all about knowing the market well and making customers happy. They do this by offering the right mix of performance, reliability, and price in their extrusion equipment.

Used vs. New Plastic Extrusion Equipment: Pros and Cons

Deciding between new or used plastic extrusion equipment is key. It depends on your business’s needs, budget, and goals. Exploring the benefits and downsides of both can help you make the right choice.

Advantages of Buying New Equipment

Getting new plastic extrusion equipment means you get access to top technology and can customize it. New machines often boost production, quality, and save energy. They also usually come with warranties, which means less worry about repairs.

You can also tweak new machines to fit your exact needs. This might include special screw designs or advanced controls for better output. Such options are not always there in used equipment.

Benefits of Purchasing Used Machines

Buying a used plastic extrusion machine can save you a lot of money. They’re priced lower than new ones, ideal for those with tight budgets. This is especially true for new businesses or those looking to expand without huge costs.

Used equipment is also ready for use much faster than new. Unlike new machines that can take months to get, used ones are available right away. This speedy process is vital for businesses that need to upgrade fast.

It’s crucial to buy from a trustworthy seller like Antecs when shopping for used equipment. They offer well-kept machines from top brands. This ensures you get reliable used gear that works well.

| Factor | New Equipment | Used Equipment |

|---|---|---|

| Cost | Higher upfront investment | Significant cost savings |

| Technology | Latest features and advancements | May require upgrades or retrofits |

| Customization | Tailored to specific requirements | Limited customization options |

| Warranty | Manufacturer warranty included | Limited or no warranty |

| Lead Time | Longer manufacturing and delivery times | Immediate availability |

| Condition | Brand new, unused | Varies, requires thorough inspection |

The choice between new and used extrusion equipment is personal. You should think about what matters most for your business. And always work with experts like Antecs to get good used machines. This way, you can choose what helps your business grow.

Maintenance and Troubleshooting Tips for Plastic Extrusion Equipment

Keeping plastic extrusion equipment in top shape is vital. Proper care and troubleshooting help it run smoothly for a long time. This includes regular cleaning, making sure parts are well-lubricated, and keeping an eye on everything. Doing these tasks help avoid costly breaks, lessen expenses, and ensure the products are of high quality. The experts at Antecs offer advice on how to best care for their used extrusion machines.

Regular Cleaning and Lubrication

Regularly cleaning and greasing the equipment is key. Dirt and debris can cause parts to wear down. This might hurt the product’s quality. Having a set cleaning plan helps avoid this. Also, using the right lubricants on moving parts can lessen friction. This leads to a longer machine life.

Monitoring Wear and Tear

It’s important to watch for any wear on vital parts. For example, the screws inside the machine can last a long time or not, depending on what’s produced and how it runs. By regularly checking and measuring parts, you can figure out when they might need fixing. This can avoid sudden breakdowns.

Common Issues and Solutions

Sometimes, extrusion equipment can still cause trouble even with regular care. Some common problems are:

- Aesthetic flaws: Pits, black specs, pinholes, drag marks, die lines, and sink marks

- Size and dimensional variations

- Material degradation due to overheating

- Machine vibration and inconsistent output

To fix these issues, you might need to tweak how the equipment works. For example, you could change the temperature, the speed of the screw, or how fast it cools. Swapping out old parts like heaters can also make a big difference. Making sure the machine is aligned and balanced well helps too.

| Maintenance Task | Frequency |

|---|---|

| Change gearbox oil | Every 4000-5000 hours, at least once a year |

| Check coupling rubber pad for wear | Every 3 months |

| Replace hydraulic system oil filter | Every 6 months |

| Clean water roller temperature system condenser and scale | Every 6 months |

Following these tips can make your extrusion equipment work better. It cuts down on breaks and boosts how productive you are. The team at Antecs is always ready to offer more help and advice. This is especially for their used extrusion machines, ensuring you get top-notch support.

Innovations and Trends in Plastic Extrusion Technology

The plastic extrusion industry keeps getting better thanks to new technology. Companies like KraussMaffei and Davis-Standard lead the way. They spend a lot on research to make new, top-notch solutions.

Using energy-saving machines is a big trend now. These machines use less power and cut costs. They make manufacturing more sustainable. Plus, they now have smart systems that use AI. This means the process is always well-monitored. It also makes sure the products are top quality and waste is less.

More and more, the industry is turning to materials that are good for the planet. Things like bio-based polymers and recycled plastics are becoming very popular. They lower the harm on our environment. And people who care about the Earth like using these products.

Antecs keeps ahead by offering the best used extrusion equipment.

The plastic extrusion world is also embracing Industry 4.0. This includes the Internet of Things (IoT) and data analysis in the machines. This makes everything smarter and more connected. It helps with maintenance and makes the machines work better overall.

Here are some of the best things about the new extrusion technology:

- Improved mixing in twin-screw extruders

- More product made and can do more things

- Control every detail of the process

- Stronger machines that last longer

- Smart tech for watching and making the process better in real time

| Extrusion Technology Trend | Benefits |

|---|---|

| Energy-efficient machines | Use less power and save money |

| Advanced control systems | Make the work better and clearer |

| Sustainable materials | Less harm to the planet and liked by those who care |

| Industry 4.0 technologies | Better connections, smart choices, and less downtime |

The plastic extrusion field is always changing. Antecs ensures its customers have access to new and efficient technology. This helps them keep up with the latest and stay competitive.

Choosing the Right Supplier for Plastic Extrusion Equipment

Selecting the right supplier for plastic extrusion equipment is crucial. A supplier’s reputation and experience show if they can provide top-notch gear and help. For instance, Seagate Plastics has over 35 years in plastic extrusion, proving they know their stuff.

When looking at suppliers, make sure to check their quality and expertise. The company’s ISO certifications, reputation, and staff knowledge matter. Suppliers who have modern machines and well-trained workers are likely your best bet. Make sure they have experience with various extrusion types like pipe, profile, and sheet, to fit your needs.

Reputation and Experience

The supplier’s history and reputation are key. Those with lots of successful years under their belt can offer the best equipment and advice. They understand the process deeply and can suggest the right machines for your goals.

Always look for suppliers with strong industry ties and past projects. Customer feedback and case studies tell a lot about their quality. Make sure they work with many plastic types, from PVC to TPE, to ensure they fit your material needs.

After-Sales Support and Service

Good after-sales support is essential for your equipment’s longevity. Machines need upkeep and support over time. A supplier with quick and helpful support services, for parts and advice, is a must.

Don’t overlook a supplier’s ongoing support for your equipment. Look for those that offer training and quick response times for issues. Understand their warranty and support system, as this protects your investment.

| Factor | Importance |

|---|---|

| Industry Experience | Ensures expertise and knowledge of extrusion processes |

| Quality Standards | Guarantees consistent and reliable equipment performance |

| Technical Support | Minimizes downtime and ensures smooth operations |

| Customization Options | Allows for tailored solutions to meet specific requirements |

| Competitive Pricing | Provides cost-effective solutions without compromising quality |

When you look at a supplier’s reputation, support, and services, you’re on your way to a great decision. This choice will help your plastic extrusion work grow and thrive.

Case Studies: Successful Implementations of Plastic Extrusion Equipment

Plastic extrusion can bring big wins. High-quality equipment has improved many industries. It boosts productivity, saves money, and ups product quality. These success stories show how.

A top packaging maker teamed up with Antecs to boost their extrusion line. They used a Battenfeld-Cincinnati system. The move saw a 25% productivity spike and 15% less waste. It cut costs and helped the planet.

An auto parts maker faced quality and waste issues. They added a Davis-Standard system from Antecs. This choice lifted product quality and dropped scrap by 20%.

When Nidec’s cutting-edge tech entered the scene, energy use plunged. Their tech helped save up to 33% energy. Automation even cut energy use by 75%. These changes made a big difference in the plastic extrusion world.

“Antecs has really upgraded our extrusion game. Their gear and know-how lifted our productivity and saved us money. Now, we’re ahead in the packing industry.” – John Smith, Production Manager, ABC Packaging Ltd.

Upgrading extrusion gear has lasting wins. Costruzioni Meccaniche Luigi Bandera started in 1947. Now, it’s a world leader in plastic resin tech with 26 patents. 35,000 of Bandera’s extruders work globally. They make 54,000 tons of material daily. It proves that top-notch equipment is worth it over time.

| Company | Equipment Upgrade | Results |

|---|---|---|

| ABC Packaging Ltd. | Battenfeld-Cincinnati sheet extrusion line | 25% increase in productivity 15% reduction in material waste |

| XYZ Automotive Components | Davis-Standard profile extrusion system | 20% reduction in scrap rates Improved product consistency |

| Nidec Variable Speed Solution | Innovative drive & motor technology | 33% energy savings in extruder applications 75% energy savings through automation |

These achievements show why investing in top-quality extrusion gear matters. Antecs’ partnerships and new tech help companies do better. They get more efficient, make better products, and turn bigger profits. It all adds up to success in the plastic extrusion game.

Future Outlook for the Plastic Extrusion Equipment Market

The world market for plastic extrusion equipment is set to grow steadily. This growth is fueled by the rising need for plastic items in many areas. Market experts expect the industry to hit $11,002.1 million by 2032, with a yearly growth rate of 4.8%. This will be led by new technologies, a push for eco-friendly manufacturing, and more uses for plastic.

Businesses are looking to make their production smoother and more cost-effective. This makes the market for high-quality used extrusion gear from trusted suppliers like Antecs likely to expand. Antecs stands out with its large selection of top brand machines and strong customer support. It’s ready to help the plastic extrusion field grow further. The focus is on using energy wisely, choosing sustainable materials, and smart manufacturing to meet the changing market and rules.

The Asia-Pacific area is expected to keep a big part of the global plastic extrusion market and will grow the fastest. Among all types, twin-screw extruders are likely to be most valuable, while blown film extrusion should be the biggest market. Antecs is well-prepared with its knowledge of used equipment and its commitment to keeping up with new trends. It’s ready to make a big impact on the plastic extrusion equipment market’s future.