Plastic waste is becoming an increasingly critical issue. It is plaguing communities and ecosystems across the globe. Consumer use of plastics is rising. Develop proper solutions to collect and recycle these durable but disposable materials. This is crucial for creating a sustainable future. Plastic recycling machinery holds promise as a method of diverting waste from landfills and waterways. It also comes with its own set of environmental impacts to consider.

A Growing Plastic Predicament

Large-scale plastic production began roughly 70 years ago. Globally, it has generated some 6.3 billion tons of plastic waste. Plastics usage is accelerating in developing nations. That number may double in the next 20 years. Clearly, the amount of plastic waste being produced has far outpaced our ability to properly manage it. Without intervention, there could be more discarded plastics by weight than fish in the ocean by 2050.

Much of this waste ends up in landfills, where plastic materials can persist for centuries without degrading. What doesn’t end up in landfills often makes its way into natural ecosystems. It does this via runoff or improper disposal. This wreaks havoc on wildlife and habitats. For example, over a million seabirds, 100,000 marine mammals, and sea turtles die each year due to eating and getting caught in plastic. Microplastics have also been discovered in alarming concentrations inside fish and shellfish. This poses contamination risks across entire food chains.

Transitioning to a Circular System

Environmental organizations and governments have rallied behind the concept of a circular economic model for plastics. This contrasts with the current linear “take, make, waste” approach. Instead of treating plastics as disposable materials with little inherent value, a circular system aims to maximize the utility of plastic products. It also enables proper recovery and reuse.

Plastic recycling machinery serves as a conduit within the circular model, allowing for the processing and mechanical remanufacturing of used plastics into new products. This closes the loop on plastic waste generation while reducing usage of costly virgin materials. What used to be discarded as trash is transformed into economic and ecological savings under this regenerative system.

The Recycling Process

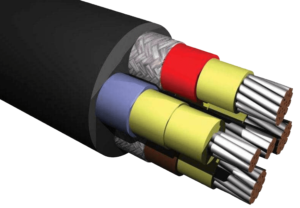

In general, plastic recycling machinery utilizes automated systems to separate, clean, grind, re-pelletize and remake used plastic materials while generating minimal emissions. Initial sorting helps group discarded plastics based on their chemical makeup, as determined by the resin identification codes found on most products. This step prepares the subsequent processes to produce higher quality recycled plastics.

Next, the plastics undergo a comprehensive cleaning to remove contaminants before entering grinders or shredders to be broken down. The resulting plastic flakes or powders are then remolded into pellets, which can be used as feedstock for manufacturing new plastic goods. Advanced systems can complete this entire sequence automatically with impressive efficiency and precision.

The Promise of Plastic Recyclers

Widespread adoption of plastic recycling machinery holds tremendous potential to reduce the overwhelming quantity of plastic waste leaking into fragile ecosystems. Diverting this waste into value-added recycling processes mitigates millions of tons of plastics from being discarded improperly annually. In a best case scenario, increased recycling capacity coupled with broader public awareness may even help curb global plastic production levels to further ease waste burdens.

If implemented strategically within localized industrial ecosystems, recycling machinery can greatly bolster the proportion of plastic waste properly managed. Plastics used in packaging, electronics, construction materials and vehicles all represent target areas recyclers hope to capture, breaking them down into usable feedstock for remanufacturing. This closed-loop industry may also stimulate economic activity and green job creation in communities housing plastic recycling plants.

Current Limitations

Despite auspicious projections, plastic recycling machinery still faces issues of economic viability, limited scope and lack of supportive infrastructure necessary to produce meaningful system-wide changes.

For one, installing and operating comprehensive plastic recycling plants demands major upfront investments, with marginal profits given the low market value of recycled plastic materials. The logistics of collecting and transporting plastic waste to treatment facilities at scale is also a massive undertaking requiring synchronized public and private coordination.

Even if these impediments can be overcome, most recycling machinery is only equipped to handle certain plastic types like PET and HDPE, which comprise just 20% of all discarded plastics today. More technology advances are needed to enable full-stream plastic recycling.

Holistic, Sustainable Systems Thinking Required

In the end, bolstering plastic recycling capacity serves as only one piece of a much larger puzzle needed to properly address the plastic waste epidemic. Truly sustainable outcomes require thinking beyond just managing waste toward comprehensive changes further upstream:

This means questioning the necessity of plastic usage in consumer and commercial products in the first place. It also means improving product designs to maximize recyclability while phasing out toxic chemical additives that hinder repurposing. Even broader efforts promoting upcycling and educating the public on proper waste disposal is necessary.

Plastic recycling machinery will fall short of its potential unless implemented in conjunction with full systems redesign. Nonetheless, rapidly advancing recycling technology and plastic circularity models provide glimpses of a cleaner future, if public and private institutions make concerted efforts to support these burgeoning innovations. The health of society and nature may very well depend on transitioning today’s throwaway culture toward one guided by sustainability through ingenuity.