The plastic injection molding machine is a super important invention in making things. It has changed how we make plastic stuff in many different industries. Let’s learn about how these machines have changed over time, how they help us make things, and why they’re so important for making plastic stuff.

Long ago, people used to make plastic stuff by hand, which was slow and hard work. But then, someone invented the plastic injection molding machine! This machine helps us make plastic stuff really fast and easy.

Over the years, these machines have gotten better and better. They can make all kinds of plastic things, like toys, bottles, and even parts for cars. With these machines, we can make lots of things quickly and cheaply.

Plastic injection molding machine are like magic! They take melted plastic and turn it into cool shapes. These shapes can be anything we want, from simple toys to complex parts for machines. It’s amazing how these machines work!

Because of these machines, we can have lots of plastic stuff that makes our lives easier and more fun. But we also need to be careful with plastic because it can harm the environment if we don’t recycle it. So let’s keep using these amazing machines to make cool stuff while also being kind to our planet!

Let’s keep learning and exploring how these machines work and how they help us make the world a better place!

Historical Development

Once upon a time, back in the late 1800s, a special material called celluloid was invented. People were amazed by its uses, but it wasn’t until 1872 that something truly remarkable happened. A man named John Wesley Hyatt made the very first plastic injection molding machine. He used it to create billiard balls from celluloid instead of ivory, which was a big deal because it saved animals and trees!

Jumping ahead to the 1940s, during World War II, everyone needed lots of plastic stuff, and they needed it fast. This led to big improvements in injection molding machines. Manufacturers wanted to make tons of plastic things quickly and well, so they made the machines better.

One big change was the introduction of screw injection machines. These machines were smarter and helped control how fast and how good the plastic stuff was made. With these changes, making plastic things became easier, faster, and more reliable.

And that’s the story of plastic making machines! It’s all about smart ideas, hard work, and making the world a better place with plastic.

Technological Advancements

Over the decades, plastic injection molding machines have undergone substantial technological advancements. These improvements have optimized the manufacturing process, allowing for faster production times, reduced waste, and improved product quality. Modern machines are equipped with computer-aided design (CAD) and computer-aided manufacturing (CAM) capabilities, enabling precise and efficient mold design and fabrication.

Additionally, advancements in materials science have broadened the range of plastics that can be used, from thermoplastics to newer biodegradable options. This versatility has made injection molding a preferred method for producing a wide array of products, from simple household items to complex automotive components.

Economic Impact

The economic impact of plastic injection molding machines is profound. They have enabled manufacturers to produce goods at a fraction of the cost compared to other manufacturing processes, such as metal forging or woodworking. The ability to produce large volumes of products quickly and at a low cost has made plastic goods accessible and affordable worldwide.

Furthermore, the automation of injection molding processes has reduced labor costs and increased the competitiveness of industries. This automation allows for consistent quality and faster production cycles, which are critical in a global market where speed and efficiency are paramount.

Environmental Considerations

Despite their economic benefits, plastic injection molding machines pose significant environmental challenges. The production of plastic products contributes to pollution and the depletion of non-renewable resources. Moreover, the waste generated by discarded plastic products has become a major environmental concern.

In response to these challenges, there has been a push towards using more sustainable materials and recycling the plastics used in injection molding. Innovations such as bioplastics and recycling technologies are being integrated into the injection molding process to reduce the environmental footprint of plastic products.

Future Prospects

Looking to the future, the plastic injection molding industry is set to continue evolving. With the rise of 3D printing and other additive manufacturing technologies, traditional injection molding is being challenged by newer, potentially more flexible methods. However, the ability to produce high-volume, high-quality products at low cost ensures that injection molding will remain an essential process in the manufacturing landscape.

Moreover, ongoing research into new materials and more energy-efficient machines promises to further enhance the sustainability and efficiency of plastic injection molding. As the global demand for more sustainable manufacturing practices grows, the injection molding industry is poised to adapt and innovate, ensuring its relevance and vitality for years to come.

Conclusion

The evolution of plastic injection molding machines has profoundly influenced the manufacturing world. By enabling high-efficiency production of plastic products, these machines have shaped industries, economies, and environments. While facing challenges, particularly in terms of environmental impact, the industry’s commitment to innovation and sustainability suggests a dynamic future. As we move forward, the continued refinement and evolution of injection molding technologies will play a crucial role in shaping the future of manufacturing.

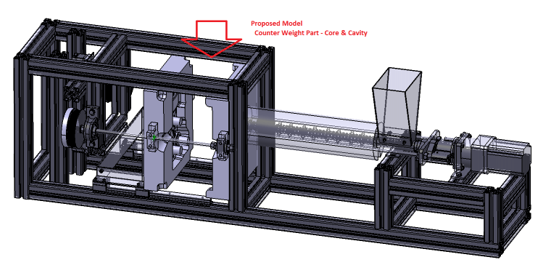

What are the primary components of a plastic injection molding machine?

A plastic injection molding machine typically consists of three main components: the injection unit, the mold, and the clamping unit. The injection unit melts the plastic and injects it into the mold cavity. The mold is a custom-designed tool that shapes the plastic into the desired form. The clamping unit holds the mold closed under pressure while the plastic cools and solidifies.

How has automation influenced the plastic injection molding industry?

Automation has significantly transformed the plastic injection molding industry by increasing production rates, improving product consistency, and reducing labor costs. Automated systems control various process parameters, such as temperature, pressure, and injection speed, ensuring high precision and quality. Robots are also increasingly used for tasks like loading and unloading components, further enhancing efficiency and reducing human error.

What are the challenges of using bioplastics in injection molding?

Bioplastics often present challenges in injection molding due to their different properties compared to conventional plastics. These challenges include higher costs, variability in material properties, and processing issues such as higher moisture sensitivity and lower thermal stability. Adjustments in processing parameters and equipment modifications are sometimes necessary to accommodate these materials effectively.

Can plastic injection molding be considered environmentally friendly?

While plastic injection molding is efficient and economical, its environmental friendliness is debatable due to issues like plastic waste and the use of non-renewable petroleum-based plastics. However, the industry is making strides toward sustainability through the use of recycled materials, advancements in bioplastics, and improvements in energy efficiency, which help mitigate some environmental impacts.

What is the future of plastic injection molding with the rise of 3D printing?

Although 3D printing offers advantages in customization and complexity without the need for molds, plastic injection molding remains superior for high-volume production due to its speed and cost-effectiveness. The future likely involves a complementary relationship where 3D printing is used for prototypes and complex, low-volume items, while injection molding continues to dominate mass production.

How do advancements in material science impact the injection molding industry?

Advancements in material science have greatly impacted the injection molding industry by providing a broader array of materials with enhanced properties such as higher heat resistance, greater strength, and improved aesthetic qualities. These advancements enable the production of more durable and versatile products and open up new markets and applications for injection molded parts.

What role does CAD/CAM technology play in modern injection molding?

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) technologies play crucial roles in modern injection molding by streamlining the mold design and manufacturing process. CAD software allows for precise and intricate mold designs, while CAM software directs the machinery used to produce the molds. This integration of technology reduces errors, decreases production time, and ultimately lowers costs.