The world's most advanced Plastic Extrusion Machines

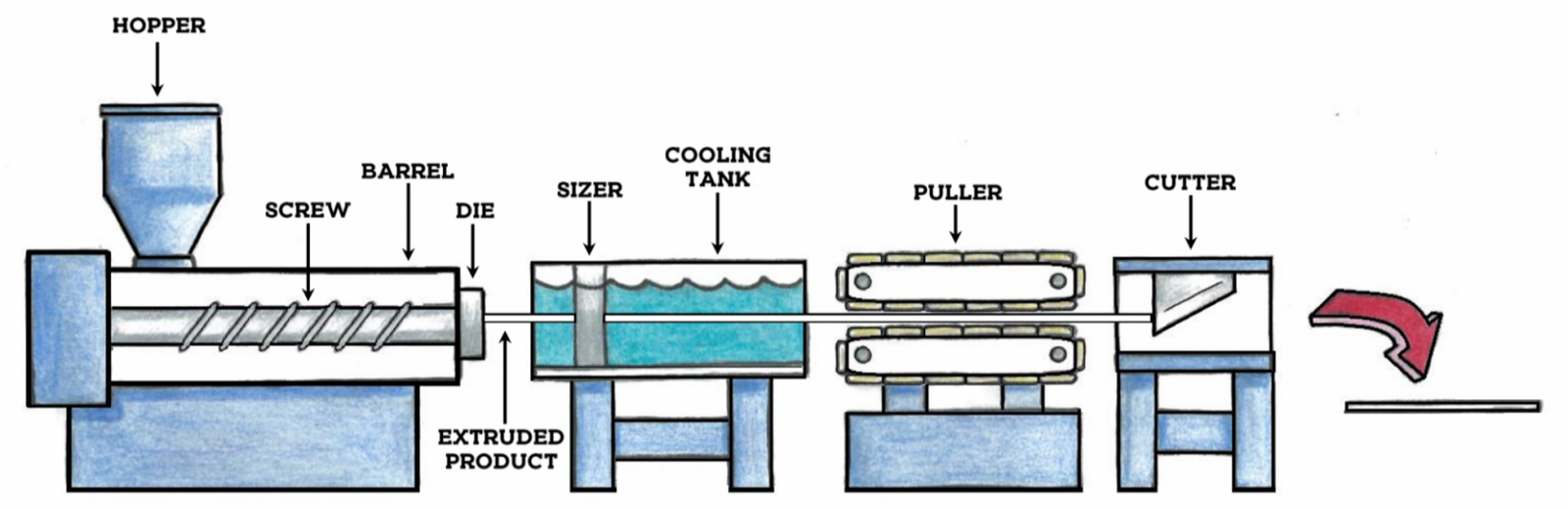

Plastic extruders and similar machines (e.g., injection molding machines, blow molding machines, calenders) are used to process plastics by applying heat and pressure to form a variety of products such as containers, bottles, or packaging materials. Each type of machine differs slightly in operation and application, but all are vital in the plastics manufacturing field.

Understanding the benefits of Antecs plastic extruder (Plastic Extrusion Machines)

Modern extruders are key machines in the field of plastics processing that utilize advanced technology and automated systems to heat, press and extrude plastic raw materials into various shapes.

Gigh Efficiency

Adopting advanced control system and automation technology improves the production efficiency and reduces the production cost.

Dexterity

It can process various types of plastic raw materials and is suitable for the production of diversified plastic products.

Quality Control

The precise control system ensures consistent dimensions and quality of the product and reduces the rate of defective products.

Environmental

Adoption of energy-saving design and environmentally friendly materials reduces energy consumption and waste generation and complies with environmental standards.

Customizability

It can be customized to meet the specific production requirements of different industries.

Easy Operation

Modern extruders are often equipped with intuitive operator interfaces and easy-to-operate control systems that make operation less difficult.

19 Years of Excellence in Plastic Extruders

Over the past 19 years, Tek Plastic Machinery Co., Ltd. has distinguished itself as a leader in the plastic extruder industry through its commitment to technological innovation and quality assurance. Since its inception in 2005, the company has specialized in manufacturing high-tech industrial plastic recycling machinery, delivering efficient and reliable solutions to the global post-consumer, post-commercial, and post-industrial recycling markets.

Our R&D team is composed of skilled engineers and technicians who have devoted countless hours to developing machines that are not only efficient but also user-friendly, focusing on durability and safety. Each piece of equipment at Tek Machinery is constructed using the highest quality materials and parts, ensuring long-term stability with proper maintenance.

With a core commitment to perfection, precision, and customer satisfaction, Tek Plastic Machinery Co., Ltd. has earned the trust and support of clients worldwide, cementing its leadership position in the international market. We look forward to continuing to innovate and provide cutting-edge solutions that drive the advancement of the plastic recycling industry.

Play Video about Plastic Recycling Machine

Why Antecs Plastic Extruders?

Advantages of Antecs Plastic Extruders

High Efficiency

Antecs extruders are designed with the latest technology to ensure high production capacity and low energy consumption, allowing clients to achieve large-scale production while maintaining cost-effectiveness.

Ease of Operation

These machines are equipped with user-friendly control systems that simplify the operation process, reduce the technical demands on operators, and minimize the risk of human error, thereby enhancing production efficiency.

Reliability and Durability

Antecs equipment is manufactured using high-quality materials and components, ensuring long-term stable operation and reduced maintenance needs, which lowers the overall cost of ownership.

Versatility

Antecs’ plastic extruders can process various types of plastic materials and can be configured to produce a variety of products such as pipes, profiles, and films, offering great flexibility to meet different market demands.

Customized Solutions

Antecs provides customized services, designing and manufacturing plastic extruders with specific configurations based on the unique needs and applications of different clients, ensuring maximum utilization of their production capacity.

Excellent After-sales Service

The company offers comprehensive technical support and customer service, including installation, commissioning, training, and maintenance services, ensuring continuous and efficient operation of client equipment.

Antecs Machinery

What applications can plastic extruders be used for?

Pipe Production

Plastic extruders are used to produce various types of plastic pipes, such as PVC, HDPE, and PPR pipes. These pipes are commonly used in construction, agricultural irrigation, and plumbing and drainage systems.

Profile Production

They are utilized for manufacturing various plastic profiles like window frames, door frames, sheets, and fences. These profiles are prevalent in construction and renovation industries.

Film Production

Plastic extruders can produce various types of plastic films, including agricultural films and packaging films. These films are used for packaging, agricultural covering, and other protective purposes.

Insulation Materials

In the wire and cable manufacturing industry, plastic extruders are used to produce insulation layers and sheathings that protect wires and cables from environmental and mechanical damage.

Composite Materials Production

Plastic extruders can also be used to manufacture composite materials, such as wood-plastic composites (WPC), which combine the benefits of plastic and wood fibers and are widely used in outdoor decking, fences, and other outdoor structures.

Automotive Parts

In the automotive industry, plastic extruders are used to make various internal and external car components, such as bumpers and dashboards.

Medical Supplies

Specific types of plastic extruders are used to produce medical-grade tubing, such as tubes used for infusion and catheters.

More Types Of Plastic Extruder

We also have more different styles of plastic recycling machine and more detailed plastic classification types of machinery.

PP PE HDPE LDPE Plastic Pellets Machine

We deliver the best solution and provide a business strategy that makes you a full professional.

Two Stage PP PE Pelletizer Machine

We deliver the best solution and provide a business strategy that makes you a full professional.

High Output PP PE PS Nylon Plastic Granulator Waste Recycling Pelletizer

We deliver the best solution and provide a business strategy that makes you a full professional.

Questions about Plastic Extrusion Machine

Learn more about Plastic Extrusion Machines questions.

Types of Plastic Extrusion Machines

Explore the various types of plastic extruders available in the market, including single screw, twin screw, co-extruders, and hot melt extruders, and their respective applications.

Applications Across Industries

Discuss the diverse applications of plastic extrusion machines in industries such as construction, packaging, automotive, agriculture, consumer goods, and more, highlighting specific examples of products manufactured through extrusion.

Advancements in Technology

Delve into recent advancements in plastic extrusion technology, such as Industry 4.0 integration, biodegradable materials, energy efficiency measures, precision control systems, and material recycling technologies.

Benefits of Plastic Extrusion

Outline the advantages of using plastic extrusion machines, including cost-effectiveness, versatility, rapid production, customization capabilities, and the ability to process a wide range of materials.

Environmental Impact and Sustainability

Examine the environmental impact of plastic extrusion processes and discuss efforts within the industry to promote sustainability through the use of biodegradable materials, recycling initiatives, and energy-efficient practices.

Choosing the Right Extruder

Provide guidance on selecting the appropriate plastic extruder for specific manufacturing needs, considering factors such as material type, production volume, quality requirements, budget constraints, and available technology options.

Get a better Plastic Extruder Machines

With 19 years of experience in machinery manufacturing, we will customize machinery to fit your needs.