1. Introduction

The general plastic extrusion process is defined below. Most plastic extrusion processes work on the principle that the polymer melt is softer than the solid state and the melt can be shaped in some way and that upon cooling the shaped solid is strong enough to maintain the shape imparted.

Plastic extruders are also extensively used to reprocess recycled plastic waste or other raw materials after cleaning, sorting and/or blending. This material is commonly compounded with additives, such as colorants and UV inhibitors, at either the compounding step before the extrusion process or with colorant dosing equipment at the hopper of the extruder. The compounded feedstock is fed into the extruder barrel from a hopper.

Plastic extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weather-stripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel. The molten polymer is then forced into a die, which shapes the polymer into a shape that hardens during cooling. The product is pulled to the desired length and reeled or cut off.

1.1. Overview of Plastic Extrusion Machines

Twin screw extruders operate on the same principle; however, there are two screws turning inside the barrel which intermesh. Twin screw machines are becoming increasingly popular in the food and pharmaceutical industries. However, the output rates of twin screw machines are generally lower and the initial cost is higher compared to single screw machines of the same quality.

In a single screw machine, the plastic is conveyed along the barrel by a single screw. The turning of the screw causes the plastic to rub against the inner surface of the barrel. This, in combination with increasing pressure, causes the plastic to heat and eventually melt. The molten plastic is then forced through a die at the end of the barrel to form the desired shape.

There are many plastic extrusion machine designs available in the market; however, they generally fall into two categories: single screw and twin screw. The primary function of the extruder is to take in the plastic, compact it, melt it, and convey it to the die to form the final product. This is accomplished by the turning of a screw inside a barrel. The plastic granules are poured into the hopper at the top of the extruder and make their way through the length of the machine. The plastic granules are heated as they are compacted and conveyed along the screw.

1.2. Importance of Efficient and Reliable Production Solutions

The importance of production machineries, which are efficient and reliable, is a known fact. Downtime of the machine means a direct loss in production and thus loss of a customer or a product. Requirements are such that today machine manufacturers have to guarantee a minimum of 90% (often 95%) uptime over a year for a client to purchase their machine, and many processors require even higher levels. In some cases, unscheduled downtime can even damage the machine or the product. This is often the case in an extrusion process because of the long cycle times involved. A damaged product may lead to more downtime if a machine has to be stopped and cleaned, and can lead to further problems if the damaged product has been used further downstream in the fabrication process. Additionally, with ever-decreasing profit margins and increasing competition due to global market forces, it is essential that a processor reduces costs to a minimum. This has led many companies to replace older, less efficient machinery with more modern, often more capital-intensive equipment. This is because most modern equipment has been designed with emphasis on minimizing operating costs, through reductions in both energy consumption and manpower requirements.

2. Advantages of Antecs Plastic Extrusion Machines

Antec’s single screw extruder sets the standard in reliability, performance, and cost-effectiveness. This is achieved by innovative design features only offered in this extruder. The most important feature of the screw design is the constant pitch and variable depth of the flights. This allows for the most efficient use of the plastic material across a broad range of applications and material types. This means that processing rates are increased up to 30% for the same screw diameter when compared to more conventional single flighted screws.

The improved performance is also enhanced by the already proven drive system design offered with the entire range of Antec extruders. The drive system offers the best value with a combination of high torque, high speed, and a motor that matches the highest efficiency to the screw design. All of the standard extruders offer a 10-stage gearbox, and the latest enhancement has been made for the energy-efficient direct drive system, which has already proven an 11% reduction in energy consumption over an 8-month period. With the energy crisis and rising energy costs, this makes a huge savings in running costs over a period of time. The energy-efficient direct drive system is the best solution offered in the market today for reducing energy costs in plasticizing. This system has been the reason behind the sale of several extruders on the basis of payback via energy savings.

Now the most important factor for extruder reliability is temperature control and material recovery. The vented and non-vented extruders in the Antec range offer the best possible solution to this with a combination of the smooth operating screw and the most efficient thermal exchange in the processing section. The variable pitch and depth of the flights allow for a very rapid recovery of the plastic material, thus reducing residence time. The processing section barrel temperature is accurately controlled by the best thermal exchange of the barrel and the very low energy input of the latest energy-efficient heater or heaterless barrel designs. Temperature control is further enhanced by the use of ceramic heaters and a controlled cooling air system for the motor.

The vented screw design extruders provide the best solution for highly moisture-sensitive resins, which are difficult to process with conventional single screw extruders.

2.1. High Productivity

One way to increase productivity is to reduce downtime in the extrusion process. Edenfeld pointed out that one of the biggest potential time-wasters is the need to clean the screw and barrel of an extruder that has been run with a temperature-sensitive material. “Over time, many materials degrade,” he said. “To clean the system, you need to heat up the extruder and pull out the screw. Then you have to push out any material left in the system and take it apart for further cleaning. At high screw speeds, this can equate to a lot of wasted production time.”

Parsen agreed that eliminating the need for unmelted polymer to be manually removed from an extruder can make a big difference in productivity. One solution to this problem is the use of mixing sections and screws designed specifically for processing the polymers in question. These metals can also help reduce compound and extrudate temperature variation. “Non-uniform temperature is a main factor causing extrusion defects and waste of time and materials in product quality fixes and rework,” said Jeffrey A. Myers of NFM Welding Engineers.

The chair of the CRMCA’s Board of Directors, Pierre G. Villere, had pointed out that an automated material handling system can also greatly increase production rates by minimizing forklift transport and storage of materials that are to be run on an extrusion line. “Work in Process can make up as much as 25 percent of a manufacturer’s inventory costs,” he said. “The productivity gains from replacing manual material handling with technological solutions can be an important factor in a highly cost competitive market.”

2.2. Consistent Quality Output

One of the key requirements of film/sheet in the present context is the increasing demand for consistent quality material. Earlier industrial fabricators of film and sheet could utilize off-grade, slow down or shut off a process and immediately revert back to prime grade resin material. This practice is no longer economical. Today, processors demand on-line and off-line film thickness measurement with close tolerance and SPC production.

Production economics typically do not allow for slower, cheaper run off resins to be utilized for running lower quality product. At some point during the transition from prime to off-grade resin, or attempting to run a wider, thicker gauge product, the extrusion process will fail. Steps have been taken in recent years by suppliers of extrusion machinery to design systems that are more capable of handling recycled material. Nevertheless, consistent quality expectations for product manufacturers will likely remain unchanged.

Processors also desire the ability to quickly and easily change the gauge or density of the product being produced. This is most simply accomplished by a faster or slower line speed. Alternatively, variable output extruders are available with technology to change the thickness or width of a product several times in one production run. While this technology is quite intriguing, it is typically limited by a narrow range of thickness or width variability. Nonetheless, the ability to achieve gauge changes without having to stop and adjust the dies or tooling is a clear benefit in terms of productivity.

2.3. Energy Efficiency

Energy saving is becoming of great importance in all industries in the world. With increasing costs of energy and global competition, it is important to reduce the energy used to manufacture products. Plastics processing is no exception, with its huge energy usage worldwide. In the UK, the Carbon Trust states that the energy bill of the industry is around £1 billion a year. Two-thirds is used by the processing machines, and the other third is used in drying raw materials and pre-heating before processing starts.

The energy usage can be split into two areas: horizontal and vertical. The horizontal energy is the energy used in moving the screw and overcoming the viscous drag of the polymer against the barrel and through the die. Calculation of this energy can be quite complex and is usually done by the machine manufacturers to work out the best motor and drive system to use on the machine. An approximation of this energy can be given by calculating the specific energy input, which is the kWh used per kg of polymer processed. The vertical energy is the energy generated from shearing the polymer. This energy directly relates to the quality of mixing and the homogeneity of the melt. High vertical energy can cause polymer degradation, so it is generally undesirable.

Measures to lower both horizontal and vertical energies usually center on the screw. High-efficiency screw designs can greatly reduce energy usage. High-efficiency screws tend to give better output rates; however, this must be balanced with residence time of the polymer in the extruder to ensure the quality of the melt is not compromised. Residence time can be altered with larger pitch screws, although this can increase the vertical energy. New drive systems have also helped to improve energy usage. Frequency-controlled drives allow different parts of the process to have different energy and output levels, and workload-responsive controls can adapt the machine’s output depending on the workload required. This helps reduce the amount of wasted energy used when a machine is left idling.

3. Key Features of Antecs Plastic Extrusion Machines

The parallel twin screw extruders are specifically designed for the efficient extrusion of thermoplastics. The integrated drive technology and easy user interface are just a few of the features that further emphasize a successful outcome. These machine designs incorporate various features that facilitate high productivity, outstanding product quality, and easier operation.

One of the key design features is the patented screw design with its specific screw, barrel, and screw housing configuration that is matched to the processed material. This feature ensures a gentle, controlled plasticizing process resulting in a reduction of the processing temperature. Lower processing temperatures combined with a high level of mixing energy avoid damage to the thermoplastic and/or degradation of thermally sensitive materials. This is very important for those that process high-end engineering polymers. Damage that may occur using conventional extrusion machines can result in premature failure of the processed product.

Another feature is the direct drive torque motors that have been designed to provide optimum torque at all speeds, offering maximum output for all processed materials. These motors have been designed to provide a maintenance-free solution. This design eliminates the need for a fan and cooling systems and also eliminates heater bands, which is a common method used to heat and control the temperature of the barrel. The electric heaters on the barrel are far more efficient and precise compared to heater band systems. This design reduces energy usage and provides further control of the barrel temperature, leading to more energy savings and better quality extruded product.

3.1. Advanced Control Systems

Plastic manufacturing concepts are not paradoxical – although they are individualistic and diverse in terms of processes, raw materials, and products. It is clear that industry experience is passed on from professional to student and therefore practical experience is a great conference theme.

Facilitating a knowledge exchange between industry and academia is easier said than done, however, as the two communities often have differing goals and measures of success. Success in manufacturing is earning a profit by producing quality products as quickly and as cheaply as possible. Success in the academic realm is typically measured by publications, graduates, and academic progress. This conference is designed to bridge the gap between industry and academia by mixing presentations, which are more formal and encourage publications, with networking events that enable industry and academic personnel to establish relationships and mutually beneficial community. Step one is an essential commitment to advanced control systems that can be a foundation for future conferences.

3.2. Versatile Extrusion Capabilities

By far the most notable characteristic of thermoplastic materials is the ease with which they can be converted into useful shaped articles. This capability, to take just about any form imaginable, is the result of the unique behavior of molten thermoplastic materials which, under the influence of heat and pressure, become highly fluid and hence are eminently suitable for processing by a variety of shaping techniques. Of the several processes available, extrusion is particularly versatile because it is capable of meeting a wide range of product, rate of production and tooling cost requirements. These make it a highly cost-effective method in comparison with others, such as injection molding which offers less on design flexibility and more on cost per part.

The product of an extrusion operation, known as an extrudate, is the result of forcing a material through an orifice or die to produce an item with a consistent cross section. This simple definition masks the sophistication of the process and the abundance of products which may be made, ranging from the common-or-garden plastic shopping bag to a precision medical catheter. The essentials of the operation involve the melting of the polymer in a moving screw and conveyance to the die.

TEMPERATURE TIME PROFILE The way in which temperatures are manipulated and controlled in the vicinity of the die has a profound effect on the extrudate and the rate of production. A complex product, such as a medical tubing with thin walls and a huber point needle, is best achieved by accurate temperature control as it is the build-up of pressure in the die which forces the materials into any remote corners of the tool. This kind of product may necessitate a die with multiple orifices and the use of tooling to bond several extrudates into the desired tubing. By contrast with this, a simple product like a plastic rod or profile may suffer from die swell and distortion unless a free-extrusion type is utilized. The rate of production of such rod may be relatively high and so the economic production of a wide range of products often demands more than one extrusion line.

3.3. Easy Maintenance and Operation

The demand for extrusion machines has increased as production processes are becoming more complex. Manufacturers have to ensure the equipment they install is highly efficient, reliable, operator-friendly, and easy to maintain. Extrusion machines are used in both recycling and new product manufacturing, and the market for all types of extrusion machines has grown.

Having time to produce the end product is a common factor characteristic of any extrusion processor since it helps in maintaining a competitive edge in today’s tough global market. Thus, simple and reliable extruder designs are preferred. An extrusion machine that has unpredictable outcomes is something a processor wishes to avoid. The functionality of an extruder highly depends on its design and the sequence of operations. To get the best results, an extrusion machine should be able to carry out every operation up to the final product while it is still in its molten state, i.e., not having to wait for it to cool before performing the next operation. Such processes are common in film and sheet extrusion and also profile extrusion. Step by step extrusion is the ideal preference here.

The UNI-TWIN extruders have a parallel and conical twin design and are versatile in the material they can process and the range of operations they can do. They also come in various L/D ratios to suit the application. Profiles, pipe, and screws are examples of products that change shape along their length, and this is where L/D flexibility is important. Too much heat generated from mechanical energy input could be damaging, and in some cases, melt fracture can occur. An extrusion machine should be capable of conveying and melting the material with the least amount of mechanical energy input. This is attainable with a single screw design, and screws can be tailor-designed to suit a particular material.

The successor of a standard single screw machine is a screw extruder, which is now becoming familiar to many processors. This is a machine that has only a screw and a drive system and does away with a conventional barrel. The material is contained simply by the encasing of the screw, and it is possible to control the temperature and pressure by manipulation of the torque and screw rpm, which is relative to the amount of heat generated. This type of extruder is the simplest and most effective way of extruding material. Compensation in this case is not an issue.

4. Applications of Plastic Extrusion Machines

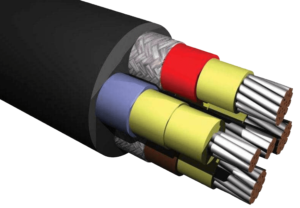

The processing of plastics by extrusion is important in a great variety of applications. The extrudability of a thermoplastic is generally defined by its ability to be formed into a product of satisfactory quality and to perform adequately in an end-use situation. Certainly, the greatest number of products are fabricated into simple or intricate solid shapes (rods, bars, and tubing) for mechanical use or to be cut into shapes for subsequent use in other products. In some instances, the extrusion is for the purpose of using the inherent surface texture, which may be controlled by proper screw and die design. A most remarkable feature is the use of extrusion for production of a wide range of shapes and sizes of items for subsequent incorporation in fabricated assemblies – for example, automobile door and window seals, electric cable coverings, machine tool trims, or laminate constructions of various types. Films and sheeting of a wide variety of types are produced and are used in food packaging, bags and pouches, tape and record media, construction, and agriculture. Consideration can be given to custom compounding of thermoplastic materials to achieve specific properties to be followed by extrusion as the most practical means of product fabrication. At the present time, there is considerable interest in use of extruders and extrusion systems specifically designed for thermoplastic elastomers and there is excellent growth potential in this field.

4.1. Packaging Industry

Solutions to the myriad opportunities and challenges in the packaging industry are central to many of today’s extruder innovations. In packaging, the name of the game for Extrusion 2002 is improved production efficiency. The continued substitution of alternative materials by plastic resins offers the potential to grow volume while offering extruders the opportunity to gain a larger share of the business due to the low cost, high output nature of plastics processing. Packaging, however, can be somewhat demanding of the extruder as many in the industry require a custom job in order to create film for a specific application. Another factor in the packaging industry is the recent increased public and private involvement and preference for recycling materials which has its pros and cons. Post-consumer recycling is driving demand for higher quality in rHDPE and PET resins, while recycling within the plant presents an opportunity to reuse lower grade resin and off-quality product into less demanding applications. This is all about efficiency in material usage. The plastics industry is also subject to continued scrutiny by environmental agencies and the public and therefore must state a commitment to cleaner, more efficient processing methods. An example of direct machinery innovation to produce a more environmentally friendly product is the development of resin blends which create degradable plastics. These plastics are designed to bridge the gap between the high efficiency and low cost of regular plastics and the environmental benefits of more expensive but less efficient alternatives such as paper and cardboard. The extruder must take into consideration changes in processing equipment to produce this new age of plastics.

4.2. Construction Industry

The use of PE pipe in construction has been growing for the last decade. This is due to PE pipe’s resistance to corrosion, its flexibility and ease of installation, its cost effectiveness, and its safety. The durability of PE pipe in silt applications, its environmental benefits, its resistance to corrosion from acids and brackish waters, and the fact that it does not support biological growth all make PE pipe a great choice over alternative materials, especially in tough, demanding environments.

The use of PE pipe within the mining and construction industry has been, and continues to be, an integral part of these projects. The tough, chemical resistant, low and high-temperature rating, and high-impact strength of PE pipe make it a reliable choice in these applications.

PE’s long-term life cycle and low maintenance cost, compared to other materials, make it an attractive option in these demanding applications. Many large mining projects are replacing old systems constructed of traditional materials such as concrete, steel, and rubber with PE. This is due to the fact that PE is easier to install, its flexibility allows it to handle swift changes in elevation, and it does not require maintenance due to joint failure. Switching to a material that does not wear out and require costly shutdowns for repair work is a substantial advantage.

4.3. Automotive Industry

The automotive industry has long made use of plastic extrusion processes for various applications. Most common in recent years has been the change towards plastics for making profiles to replace metal parts. This has paid off for the industry in that it is typically cheaper to extrude plastic and the plastic part ends up being much lighter than the metal counterpart. This in turn results in less wear on the automobile over time due to better fuel efficiency, but the most important factor is the environmental benefit. This relates to the same parts being produced once again through a process called foaming discussed earlier in the paper. Plastic extrusion machines have the capability to change the density of a profile during the extrusion process, and it is then cut to form the desired part. With lightweight still being a concern for the aerospace industry, aircraft manufacturers have also begun to make the switch to plastics for the majority of internal parts. This process has already been seen to be effective in increasing the longevity of parts due to less warping over time than metal.

5. Factors to Consider When Choosing Plastic Extrusion Machines

Choosing the right extruder is critical for greater productivity, longer life, and quality products. Here are some guidelines for establishing what might be called the most cost-effective machine:

– What are the future requirements for the extruded product? – What are the expected long-term business needs? – What are the specific cost requirements for the new product which can be matched directly to the extruder? – What are the critical level quality requirements for the new product? – What maintenance staff and skills are available today and anticipated for the future? – What are the skill levels of the operating personnel? – What are the space limitations for the extrusion line? – What are the power and utility availability and limitations for the new line? – What are the specific new machine technological features which could improve product quality, reduce downtime and minimize operating costs? – Cost-comparison shop. A thorough analysis is essential to assure that the best value extruder is purchased. A cost-comparison often can reveal that a machine priced higher by a competitor actually is the best buy due to long-term considerations like energy usage, maintenance, and part quality. The hourly cost of running an extruder can be determined by dividing the total cost per year including depreciation by the annual operating hours. Be certain to call on the expertise of all levels of plant personnel when comparing the various machine features. Often long-term maintenance and operating staff can best determine the machine which is most cost-effective to operate and results in a high quality product.

5.1. Production Capacity Requirements

We should be cautious in our approach to projecting likely requirements for future production capacity. The capital costs of polymer processing equipment are high and the potential costs of getting the decision wrong are therefore high. Underestimating future production requirements can result in expensive plant modifications or even complete production line replacements if processing machinery becomes a bottleneck through lack of capacity. On the other hand, over-specifying can result in excessive capital investment, reducing profitability and competitiveness. In our experience, many polymer processors target a notional 20% growth in capacity within a five-year period. This provides a useful figure for assessing equipment and technology options, even if the assumptions behind it are rarely articulated and can vary widely between different companies implementing different growth strategies. An alternative method is to consider the impact of an increase in market share on volume requirements and relate this to an expected rate of productivity improvement. Simulation using the production scheduling tools detailed in section 5.2.3 can be a very effective way of quantifying volume requirements and assessing the impact of changes in processing technology.

5.2. Material Compatibility

Considering the number of available resins and the continuously increasing development of new plastics, there is a need for machines which are versatile and capable of processing a large range of polymers. The selection of a system of machines must be capable of extruding the range of materials which may be demanded by future product developments. Modern extrusion machines are designed to process many different resins with only a minimum of screw and die changes. It is common to have grades of the same resin from different manufacturers which may have slightly different flow characteristics. In general, it is difficult to use the same screw and die to produce optimum quality product from resins which vary widely in their rheological properties. However, it is possible to produce acceptable product from a family of similar resins by adjusting the processing conditions. Some low-cost machines may be suitable for running only one or two materials. This may be a disadvantage if the materials concerned become obsolete or if the shape of the product becomes unsuitable for that method of production. It is not inconceivable that a company which does not extrude plastics at present may wish to do so in the future, and it must be remembered that machine designs with a high obsolescence rate do not represent good value. High production machines for products such as extruded pipe may specify that they are only suitable for running one material. This may be the case if the design output is based on maximum screw and barrel RPM and an output to power consumption ratio which would not be achievable with a more viscous material. A two-material changeover with pipe extruders which are currently running one material can sometimes be an easy method of increasing production during periods of low demand for the primary product.

5.3. Cost and Return on Investment

It can be difficult to put a figure on the cost of a machine, as expenditures can range between initial purchase cost, maintenance costs and downtime. In terms of purchase price, extruders are not cheap. Small and medium size machines can cost several hundreds of thousands of dollars. The outputs and prices can mean that extruders take many years to pay for themselves (up to 10 years in the worst case scenarios), and a lot can happen in the plastics industry in these years. Companies purchasing an extruder should be confident that they will have enough business to keep the machine busy for its workable life, or have a use or market for the products they will be producing.

There are some cost benefits to be found. Extruders are generally more efficient than injection moulding, particularly at lower output rates. Maintenance costs are generally quite low, particularly if machine operators are educated in correct procedures. Screw and barrel wear rates can vary between excessive and very low, depending on the machine, the materials and the expertise of the operators. A good screw and barrel can last several years, and this is vital to maintaining melt quality. A machine with a frequently changing screw and barrel will have high downtime costs and lowering quality product. The energy efficiency of an extruder also varies depending on size and type, but generally very quiet screw and energy efficient barrel will yield an energy efficient machine. A company that has calculated running costs over machine workable life and that has employed energy efficient methods can plug the difference between high purchase cost and return on investment.

“Extruders almost always pay for themselves eventually” (Christer Sjöström). The point of return can be hard to define, but once the machine has broken even, the profit from it is clear. This has led to many orders for extruders to replace production methods, which while inferior in quality, have lower capital costs.

6. Maintenance and Troubleshooting of Plastic Extrusion Machines

The maintenance and troubleshooting of plastic extrusion machines is very essential for the efficient operation of these machines. The first thing in maintenance is to develop and maintain an effective mold maintenance program. Poor tool maintenance will certainly lead to increased downtime, part quality problems, and higher operating costs. Check the written steps recommended by the equipment and mold suppliers. These are quite specific and should be followed closely. Some of the maintenance can be done while the mold is still in the press. For preventive maintenance, disassemble the mold and clean all components at regular intervals. This is especially important when abrasive resins are run. Before cleaning any components, always consult the supplier to be certain that the cleaning method used will not damage the tool.

Internal diameter cleaning is notoriously difficult to carry out effectively. Always try to clean in the direction of the flow to avoid potential surface damage impeding material flow in future production runs. Inspect the mold for wear after prolonged production runs. Signs of wear to the parting line will indicate mold damage. Always try to rework the damaged area to avoid high maintenance costs. All mold welding or part rework should be accompanied with re-hardening as this is often the cause of part quality problems and tool damage.

The second best practice is plasticating unit maintenance. A poorly maintained plasticating unit is a major source of in-process instability, scrap, and part quality problems. Screw recovery is the measure of how efficiently a screw retrieves heat from the barrel and it must be fully optimized in order to avoid process inconsistencies. Screw wear will increase screw recovery time as more shear will be done to achieve the same melt temperature, thus causing part quality problems. Regular measurement of the melt temperature at the nozzle will give an indication of any excessive screw wear. Always consult the screw and barrel supplier before ordering new parts. High torque and low rotational speed is a method of minimizing wear to the plasticating unit, as the use of high screw speeds will lead to shortened machine component life. Always inspect the air cooling system for the barrel. Any inefficient cooling will result in melt temperature inconsistency and excessive heat will degrade the material. Always store screws and barrel carefully to avoid deformation between changeovers.

6.1. Regular Cleaning and Lubrication

Keeping the extruder clean and properly lubricated is essential to efficient operation. The screw, barrel, and die should be cleaned regularly with resin or a cleaning compound to prevent material degradation or contamination. The frequency and extent of the cleaning will depend on the type of material being run and the previous run. Abrasive materials such as many filled compounds may require more frequent cleaning at shorter intervals. In these cases, it may be cost-effective to run the abrasive material in a less expensive extruder/line dedicated to that material; economics will determine if the output increase of the regular line will offset the increased cost of running the material at a later time. Proper purging procedures should be followed when changing materials or taking extended shutdowns to prevent degradation or contamination of on-spec product. Screw pullers and rotation devices are available to allow for easier/quicker screw removal for the cleaning process. In extreme cases of barrel scoring, a process called barrel boring can be done to restore the extruder to proper operating condition.

The screw and barrel are the heart of the extruder and must be properly maintained. A worn screw will lead to degraded output and poor melt quality. A rule of thumb is to always keep a new spare screw and barrel for a critical job running with the possibility of using it to improve the quality/cleanliness of the output. Wear can be evaluated by monitoring motor load/amps, melt temperature, and checking the dimensional tolerances at various sections of the screw. A worn screw will have decreased output with increased amps and lower temperatures. A properly working screw will develop approximately 3-5 HP/lb depending on the type of material. Melt quality can be evaluated by checking the shot weight consistency and gate pressure if a rheology or capillary rheometer is not available. Checking the dimensional tolerances of the screw can provide an indirect indication of the melt quality. High screw wear can often lead to an increase in pressure at the discharge end and thereby an increase in temperature, which can cause degradation. A barrel with worn or damaged heaters and/or cooling passages will not provide uniform temperature control. A modern extrusion system will have a screw made of through-hardened tool steel and a barrel lined with an abrasion and corrosion-resistant alloy such as an iron-based alloy with tungsten carbide. The use of higher abrasion and corrosion-resistant materials for both the screw and barrel can provide longer life and increased productivity.

6.2. Identifying and Resolving Common Issues

All extrusion processes are systematically alike in that a raw material is melted and formed into a continuous profile. Process control problems occur when the condition of the melt or the conditions of forming are such that the process does not produce acceptable product. In order to provide consistent production and high-quality product, the operator must be able to identify the problem. Some problems may be very specific, however many are usually symptoms of a more general class of problems. In any case, the ability to isolate and correct the problem quickly can be of major economic importance.

Be sure you understand the problem. When trying to resolve any issues, it is important that the operator understand the problem. Is a problem a result of a process upset, or is it caused by a change in the operating conditions of the extruder? Problems caused by process upsets are often self-correcting when the upset has passed, examples are foreign particles in the resin or air pockets. Corrections for these problems are usually temporary overrides of system settings until the product is back to normal. Problems caused by changes in operating condition may be unsupported. At times, no changes will be noted in system settings but the product is different. This is a result of operator familiarity and the ability to produce different product while making no changes to the machine. With the increase in computerized control systems, many problems can be traced to a change in system settings. The ability to retrieve and compare old settings to current ones can aid in restoring normal product.

6.3. Safety Measures

To ensure optimal safety for the personnel operating the lines, the WPS compounding extruder is equipped with a number of safety features. In addition to meeting or exceeding minimum safety requirements, WPS can customize the extruder to include a number of other safety features and meets CE safety requirements. Although specific safety features may vary depending on the customized extruder, some of the standard safety features are as follows.

The primary safety feature is the barrier screws, including a feeding barrier screw and a cut-off screw, that seal the extruder from the outside atmosphere. There should be no reason to access the extruder when it is in operation, and the barrier screws are designed to prevent any material leakage to the outside atmosphere. This guarantees operator safety from sharp rotating machinery and high-pressure material. Any remaining product in the extruder can be a hazard to the operator when starting up the extruder after a shutdown. The WPS barrier screws are also designed such that most material can be dumped or extruded back out, allowing for quick and easy cleaning for material changes or screw pull when the extruder must be opened. This reduces the need for operator screw pull and cleansing with the screw rotating, a hazardous operation.

7. Future Trends in Plastic Extrusion Technology

Innovation in plastic extrusion machines has generally come from the requirements in energy, repeatability, and adaptability. Energy utilization has become increasingly important over the past decade as a direct result of rising costs and environmental concerns. Recently, the main goals in energy saving have been to provide equivalent or improved production rates and part quality while reducing energy consumption. This is especially important for high-output processes such as pipe, profile, sheet, and thermoforming, where energy savings will have a significant impact on operating costs. Changes in screw design have helped achieve these goals. The improvement of blending and shearing in the extruder has resulted in overall reduction in melt temperatures, leading to energy savings. Screw efficiency has also been improved, resulting in reduced motor sizes. The high-speed and low-speed (Mfi) requirements of polymers have driven the adoption of twin-screw extruders for improved blending capabilities.

Repeatability of the process has become a key focus for quality control over the past decade. This is achieved through better understanding and control of the extrusion cycle, particularly in the measurement of melt temperature and density. Minimizing variation in these parameters will result in less part variation and rejects, thus saving money. Recent advancements in mold and die technology have led to the development of innovative solutions such as quick-release or slide plate tools. The fundamental concept of these tools is that they are the same as standard tools, but a specific component like a core or cavity can be changed, eliminating the need for a full tool. This technology reduces setup and downtime, and also provides future cost savings if a change is required.

At the beginning of the millennium, there was a surge of interest in computer control systems for extrusion processes. However, this interest has slowed down due to the lack of performance improvements and the additional cost without significant benefits. The ongoing research and development in measurement and control systems are where the industry is heading as we approach the next decade. Changes in thermal cycle control are being developed primarily to improve melt temperature control. This is being achieved through upgrades to both barrel and screw design, as well as research and development in high-quality thermal sensors and sensitivity adjustments to manage variation. Pressure and density control measurement are also seeing improvements.

7.1. Industry 4.0 Integration

The range of information surrounding Industry 4.0 enables the production system to adapt to information data technology, commonly known as cyber-system, which helps the machines in conducting requirements from planning and documenting the desired output. This means that development in data manipulation in cyberspace helps to bridge the information on what’s best for the manufacturing process to the machines, so that it reduces miscommunication between machine operators.

In an interview with one of the managers from a local extrusion factory, the reason for miscommunication is due to the machine operator not being able to identify the best temperature and pressure suited to process materials through the machines. By using smart cyberspace algorithms for the production system, the manager can already identify the best required temperature and pressure for the machine before relaying it to the machine operator. This gives a great advantage in reducing time to experiment and process raw materials through the machine.

Available with functions in monitoring and simulation-based systems, smart cyberspace algorithms are able to identify if there are any issues or problems in manufacturing a product and cross-check the intended requirement of the planned output. The same goes for the functions to acquire more information on the status and conditions of a machine. This definitely improves machine reliability and product output in a manufacturing system.

With a recent progression in web technology, which is IoT (Internet of Things), mobile access to system data and controls are possible. This means that machine status and data of product output can be accessed anywhere and anytime. The systems also include a function to notify users if there is any discrepancy happening during the production process. Access to this function will enable machine operators to take fast action when there is a problem with a specific machine, and a notification on data discrepancy will help the manager in identifying problems when monitoring machine status.

7.2. Sustainable Materials and Processes

Sustainable materials are a topic of growing interest. The traditional materials of steel (or other metals) and wood are non-renewable resources. Many consumer companies are looking towards reusing materials in their newer products to reduce the waste and materials being dumped into our landfills. This is available as state-of-the-art produced recycled resins of commodity and engineering grades offered up to FDA compliant grades for food packaging applications. The ultimate goal in recycling is to make it as cost-effective as possible while maximizing the potential of the recycled resin. The optimum situation would be the capability of taking the scrap from a line, grinding it up and transferring it to a loading system with the finished product not distinguishing itself from first generation product. Wholly integrated systems are outlined in the following points for our various extrusion lines:

Trim Recycling: We offer reclaim systems with a variety of trim presses to fit specific line speeds and budgets. Our most basic systems utilize a manual feed press as a surge device for the reclaim extruder. Automatic feed systems are available with pneumatic, auger or belt type conveyance.

Roll Feed reclaim systems offer a surge device with automatic speed control of driven nip rolls. This minimizes the extruder’s load on the reclaim material and ensures consistent feeding. Our shredder-feed reclaim systems utilize a high capacity shredder in conjunction with a heavy-duty granulator for the toughest applications. Automatic feed is accomplished with pneumatic or auger conveyance.

7.3. Automation and Robotics

Concepts of automation: In the recent years, the pressure on the production of high quality, custom-designed products of ever-increasing complexity has driven the plastics industry to explore new methods to increase productivity and quality while minimizing costs. The application of automation to the plastics industry, and more specifically the extrusion process, offers a promising means to reach this end. The basic concept of automation is the use of control systems (such as electrical, hydraulic, pneumatic, mechanical and computers), and information technologies to reduce the need for human work in the production of goods and services. In the extrusion industry, the most simple form of automation has been the use of control systems on the extruder to provide consistent operation – monitoring temperature, torque, and on newer extruders, adapting the barrel temperature zones and screw speed to achieve desired throughput and melt conditions. The use of sensors and closed-loop controls has improved the operation of mode of such modes of application, by providing feedback and immediate correction to deviation from user-defined set points. The advancements in controls technology in recent years, and a shift from mode of analog to digital control systems, has greatly enhanced the cost efficiency of such automation.

8. Conclusion

The implementation of extrusion technology in today’s plastic processing industry has already proven to be one of the most vital production tools available. Production of plastic requires various methods of preparation and forming, among them is extrusion as one of the most versatile. It can adapt to almost any manufacturing situation and produce a wide array of products. The production of extruders worldwide serves as a clear indication of how successful the technology has been in the plastic industry. With today’s demand for high quality and efficient extrusion, companies cannot afford outdated equipment and maintaining high quality production is always associated with high quality machines. Whether you want to replace older machines, advance your current production, or seek new ideas to extrude your product, it is important to have an in-depth understanding of what type of extruder, plastic plant, and extrusion process can do for you. By doing this, you can cross-examine the solutions available to best serve your production requirements. This book has provided an understanding of what plastic extrusion technology is about and what solutions are available for a wide range of production scenarios. The main point is to make a clear assessment of the machines available and how they are capable of enhancing efficiency and providing reliable production. All information gained should be valuable in making future decisions and ensuring the right steps are taken towards the advancement of your production.