-

Table of Contents

- Introduction

- The Origins of Plastics: A Historical Overview

- The Different Types of Plastics and Their Manufacturing Processes

- Environmental Impacts of Plastics: Challenges and Solutions

- Innovations in Plastic Recycling and Circular Economy Approaches

- Future Prospects: Advancements and Trends in Sustainable Plastics

- Conclusion

Introduction

Plastics, a versatile and widely used material in today’s world, have a fascinating history of making and evolution. Developed in the late 19th century, plastics have undergone significant advancements and transformations over the years. From the early discovery of celluloid to the invention of synthetic polymers, the making and evolution of plastics have revolutionized various industries and shaped our modern society. This introduction sets the stage to explore the intriguing journey of plastics, from their humble beginnings to their widespread applications in our daily lives.

The Origins of Plastics: A Historical Overview

The Origins of Plastics: A Historical Overview

Plastics have become an integral part of our daily lives, but have you ever wondered about their origins? The story of plastics begins in the early 19th century, when a young chemist named Alexander Parkes made a groundbreaking discovery. Parkes developed a material called Parkesine, which was the first man-made plastic.

Parkesine was created by dissolving cellulose in a mixture of alcohol and camphor. This new material had properties similar to those of natural rubber, but it could be molded into any shape when heated. Parkesine was a significant innovation, as it opened up a world of possibilities for the manufacturing industry.

However, Parkesine was not without its limitations. It was expensive to produce and had a tendency to crack and break easily. Despite these setbacks, Parkesine laid the foundation for further advancements in the field of plastics.

In the late 19th century, a Belgian-born American named Leo Hendrik Baekeland made a breakthrough that revolutionized the plastics industry. Baekeland invented Bakelite, the first synthetic plastic that could be mass-produced. Bakelite was created by combining phenol and formaldehyde under high heat and pressure.

Bakelite was an incredibly versatile material that could be molded into various shapes and colors. It was also heat resistant and electrically non-conductive, making it ideal for use in electrical insulators and household appliances. Bakelite quickly gained popularity and became a staple in many industries.

The early 20th century saw the development of other types of plastics, such as celluloid and cellophane. Celluloid, invented by John Wesley Hyatt, was the first thermoplastic, meaning it could be softened and reshaped multiple times. It was widely used in the film industry for making photographic film and later found applications in the production of combs, buttons, and other consumer goods.

Cellophane, on the other hand, was created by Swiss chemist Jacques E. Brandenberger. It was initially intended as a waterproof coating for fabrics but soon found its way into the packaging industry. Cellophane became popular for its transparency and ability to preserve the freshness of food.

The mid-20th century marked a turning point in the evolution of plastics with the introduction of polyethylene and polypropylene. Polyethylene, discovered by German chemist Hans von Pechmann, was a lightweight and flexible plastic that found widespread use in packaging, pipes, and insulation.

Polypropylene, invented by Italian chemist Giulio Natta, was even more versatile. It could be molded into various shapes and had excellent chemical resistance, making it suitable for a wide range of applications, including automotive parts, medical devices, and household products.

Since then, the plastics industry has continued to evolve, with new materials and manufacturing techniques constantly being developed. Today, plastics are used in almost every aspect of our lives, from the clothes we wear to the cars we drive. However, the widespread use of plastics has also raised concerns about their environmental impact and the need for sustainable alternatives.

In conclusion, the origins of plastics can be traced back to the 19th century, with the invention of Parkesine and the subsequent development of Bakelite. These early breakthroughs paved the way for the creation of other types of plastics, such as celluloid and cellophane. The mid-20th century saw the introduction of polyethylene and polypropylene, which revolutionized the plastics industry. The evolution of plastics continues to this day, with new materials and manufacturing techniques constantly being developed.

The Different Types of Plastics and Their Manufacturing Processes

Plastics have become an integral part of our daily lives, with their versatility and durability making them indispensable in various industries. However, not all plastics are created equal. There are different types of plastics, each with its own unique properties and manufacturing processes. In this section, we will explore the different types of plastics and how they are made.

One of the most common types of plastics is polyethylene, which is used in a wide range of applications, from packaging materials to toys. Polyethylene is made through a process called polymerization, where ethylene monomers are chemically bonded together to form long chains. This process can be carried out using different methods, such as high-pressure or low-pressure polymerization, resulting in different types of polyethylene with varying properties.

Another widely used plastic is polypropylene, which is known for its high strength and resistance to heat. Like polyethylene, polypropylene is made through polymerization, but with propylene monomers instead. The manufacturing process for polypropylene involves the use of catalysts and specialized reactors to control the polymerization reaction and produce the desired properties.

Polystyrene is another popular plastic, commonly used in packaging materials and disposable products. It is made through a process called suspension polymerization, where styrene monomers are dispersed in water and polymerized with the help of a catalyst. This process results in the formation of tiny beads of polystyrene, which can then be molded into various shapes.

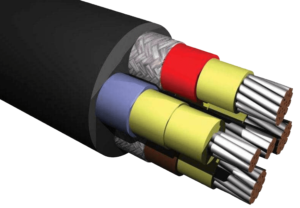

Polyvinyl chloride (PVC) is a versatile plastic that is used in a wide range of applications, including pipes, cables, and flooring. PVC is made through a process called vinyl chloride polymerization, where vinyl chloride monomers are polymerized under controlled conditions. The resulting PVC can be rigid or flexible, depending on the additives used during the manufacturing process.

Polyethylene terephthalate (PET) is a type of plastic commonly used in the production of bottles and food containers. PET is made through a process called condensation polymerization, where terephthalic acid and ethylene glycol are reacted together to form long chains of PET. This process requires careful control of temperature and pressure to ensure the desired properties of the final product.

In addition to these commonly used plastics, there are many other types of plastics with their own unique properties and manufacturing processes. For example, polyurethane is a versatile plastic that can be rigid or flexible, depending on the additives used. It is made through a process called reaction injection molding, where two liquid components are mixed together and injected into a mold, where they react and solidify.

The manufacturing processes for plastics have evolved over the years, with advancements in technology and a growing emphasis on sustainability. Today, there is a greater focus on reducing the environmental impact of plastic production, with efforts to develop more sustainable materials and improve recycling processes.

In conclusion, plastics are an essential part of our modern world, with different types of plastics serving different purposes. The manufacturing processes for plastics vary depending on the type of plastic being produced, with each process carefully controlled to achieve the desired properties. As technology continues to advance, we can expect further innovations in the making and evolution of plastics, with a greater emphasis on sustainability and environmental responsibility.

Environmental Impacts of Plastics: Challenges and Solutions

Plastics have become an integral part of our daily lives, with their versatility and durability making them a popular choice for a wide range of applications. However, the environmental impacts of plastics cannot be ignored. From production to disposal, plastics have a significant impact on our planet. In this section, we will explore the challenges posed by plastics and the potential solutions to mitigate their environmental effects.

One of the major challenges associated with plastics is their production. Plastics are derived from fossil fuels, primarily oil and natural gas. The extraction and processing of these resources contribute to greenhouse gas emissions and other forms of pollution. Additionally, the manufacturing process itself requires large amounts of energy and water, further straining our already limited resources.

Once plastics are produced, their disposal becomes a pressing issue. Plastics are not biodegradable, meaning they do not break down naturally over time. Instead, they persist in the environment for hundreds of years, accumulating in landfills and oceans. This accumulation has severe consequences for wildlife and ecosystems. Marine animals often mistake plastic debris for food, leading to ingestion and entanglement. The presence of microplastics, tiny particles that result from the breakdown of larger plastic items, has also been found in the food chain, posing potential risks to human health.

To address these challenges, various solutions have been proposed. One approach is to reduce the production and consumption of plastics. This can be achieved through the development and promotion of alternative materials, such as biodegradable plastics or natural fibers. Additionally, governments and businesses can implement policies and initiatives to encourage the use of reusable products and discourage single-use plastics. By reducing the demand for plastics, we can lessen their environmental impact.

Another solution lies in improving waste management systems. Effective recycling programs can divert plastics from landfills and reduce the need for virgin materials. However, recycling rates for plastics are still relatively low, mainly due to the complexity of the material and the lack of infrastructure. Investing in recycling technologies and facilities, as well as educating the public about proper recycling practices, can help increase recycling rates and minimize plastic waste.

Furthermore, innovation plays a crucial role in finding sustainable solutions to the plastic problem. Scientists and engineers are exploring new ways to make plastics more environmentally friendly. This includes developing bioplastics made from renewable resources, as well as creating plastics that are easier to recycle or break down in the environment. These advancements have the potential to revolutionize the plastics industry and reduce its environmental footprint.

In conclusion, the environmental impacts of plastics are a significant concern that requires urgent attention. From production to disposal, plastics pose challenges that affect our planet and its inhabitants. However, through a combination of reducing plastic consumption, improving waste management, and promoting innovation, we can work towards mitigating these impacts. It is essential for individuals, businesses, and governments to come together and take collective action to ensure a sustainable future for our planet.

Innovations in Plastic Recycling and Circular Economy Approaches

Plastics have become an integral part of our daily lives, with their versatility and durability making them a popular choice for a wide range of applications. However, the widespread use of plastics has also led to a significant environmental problem – plastic waste. In recent years, there has been a growing focus on finding innovative solutions to tackle this issue, leading to advancements in plastic recycling and the adoption of circular economy approaches.

One of the key innovations in plastic recycling is the development of advanced sorting technologies. Traditional recycling methods often rely on manual sorting, which can be time-consuming and inefficient. However, with the advent of automated sorting technologies, the process has become much more streamlined. These technologies use various techniques, such as optical sensors and air jets, to separate different types of plastics based on their chemical composition and physical properties. This not only improves the efficiency of the recycling process but also ensures that the recycled plastics are of high quality.

Another important development in plastic recycling is the emergence of chemical recycling. Unlike traditional mechanical recycling, which involves melting and reshaping plastics, chemical recycling breaks down the plastic polymers into their original monomers or other useful chemicals. This allows for a wider range of plastics to be recycled, including those that are difficult to process through mechanical recycling. Chemical recycling also offers the potential to recover valuable materials from mixed plastic waste, which would otherwise end up in landfills or incinerators.

In addition to advancements in recycling technologies, there has been a shift towards adopting circular economy approaches in the plastic industry. Circular economy aims to minimize waste and maximize resource efficiency by keeping materials in use for as long as possible. This involves designing products with recyclability in mind, promoting reuse and repair, and creating closed-loop systems where materials can be continuously recycled. By embracing circular economy principles, the plastic industry can reduce its reliance on virgin materials and contribute to a more sustainable future.

One example of a circular economy approach is the concept of extended producer responsibility (EPR). Under EPR, manufacturers are held responsible for the entire lifecycle of their products, including their disposal. This encourages manufacturers to design products that are easier to recycle and to take back and recycle their products at the end of their life. EPR programs have been implemented in various countries, leading to increased recycling rates and reduced environmental impact.

Furthermore, innovative initiatives are being undertaken to promote the use of recycled plastics in new products. For instance, some companies are developing technologies to convert recycled plastics into high-performance materials that can be used in industries such as automotive, construction, and electronics. This not only creates new market opportunities for recycled plastics but also reduces the demand for virgin materials.

In conclusion, the making and evolution of plastics have brought about both benefits and challenges. However, with the advancements in plastic recycling technologies and the adoption of circular economy approaches, there is hope for a more sustainable future. Innovations in plastic recycling, such as advanced sorting technologies and chemical recycling, have improved the efficiency and scope of plastic recycling. Meanwhile, the adoption of circular economy principles, such as extended producer responsibility and the use of recycled plastics in new products, is driving the transition towards a more sustainable and circular plastic industry. By continuing to invest in research and development and promoting collaboration between stakeholders, we can pave the way for a future where plastics are no longer a burden on the environment but a valuable resource in a circular economy.

Future Prospects: Advancements and Trends in Sustainable Plastics

The making and evolution of plastics have come a long way since their inception. Plastics were first introduced in the late 19th century as a substitute for natural materials such as ivory and tortoiseshell. Over the years, plastics have become an integral part of our daily lives, with applications ranging from packaging materials to medical devices. However, the widespread use of plastics has also led to environmental concerns, as they are known to persist in the environment for hundreds of years. In recent years, there has been a growing interest in developing sustainable plastics that can address these concerns.

One of the key advancements in sustainable plastics is the development of biodegradable plastics. Unlike traditional plastics, which can take centuries to decompose, biodegradable plastics are designed to break down into natural elements within a relatively short period of time. These plastics are typically made from renewable resources such as cornstarch or vegetable oils, making them more environmentally friendly. Biodegradable plastics have found applications in various industries, including packaging, agriculture, and consumer goods.

Another area of advancement in sustainable plastics is the development of bio-based plastics. Bio-based plastics are derived from renewable resources such as plants or algae. These plastics offer several advantages over traditional plastics, including a reduced carbon footprint and a decreased reliance on fossil fuels. Bio-based plastics can be used in a wide range of applications, including packaging, automotive parts, and construction materials. However, it is important to note that not all bio-based plastics are biodegradable, and proper disposal methods are still necessary to prevent environmental pollution.

In addition to biodegradable and bio-based plastics, researchers are also exploring the use of recycled plastics as a sustainable alternative. Recycling plastics not only reduces the amount of waste sent to landfills but also conserves energy and resources. The process of recycling plastics involves collecting, sorting, and processing plastic waste into new products. However, challenges such as contamination and limited recycling infrastructure need to be addressed to fully realize the potential of recycled plastics.

Furthermore, advancements in technology have paved the way for the development of innovative sustainable plastics. For example, researchers are exploring the use of nanotechnology to enhance the properties of plastics. By incorporating nanoparticles into plastic materials, scientists can improve their strength, durability, and thermal stability. This opens up new possibilities for the use of plastics in high-performance applications, such as aerospace and electronics.

In conclusion, the future of sustainable plastics looks promising. Advancements in biodegradable, bio-based, and recycled plastics, as well as the integration of nanotechnology, are driving the development of more environmentally friendly alternatives to traditional plastics. These advancements not only address the environmental concerns associated with plastics but also offer new opportunities for industries to adopt more sustainable practices. However, it is important to continue research and development efforts to further improve the performance and cost-effectiveness of sustainable plastics. By doing so, we can create a more sustainable future where plastics play a vital role without compromising the health of our planet.

Conclusion

In conclusion, the making and evolution of plastics have significantly impacted various industries and everyday life. Plastics have revolutionized manufacturing processes, providing lightweight, durable, and versatile materials. However, the widespread use of plastics has also led to environmental concerns due to their non-biodegradable nature and improper disposal. Efforts are being made to develop more sustainable alternatives and improve recycling methods to mitigate the negative impacts of plastics on the environment.