PP PE HDPE LDPE Plastic Pellets Machine

Antecs Machinery Introduction

Plastic pellet mills play a vital role in the modern plastics industry. They are key machines for converting waste or raw plastics into high quality pellets that can be used to produce new plastic products again. With increased awareness of environmental protection, effective plastic recycling and reuse is becoming increasingly important, and pelletizers are a key tool in achieving this.

Antecs is committed to providing efficient and reliable plastic pelletizer solutions that help our customers recycle and reuse plastics, reduce waste emissions, and lower production costs. Our plastic pelletizers are designed to be advanced and easy to operate, adapting to different types of plastic materials such as PP, PE, HDPE and LDPE, ensuring an efficient and sustainable production process.

With Antecs’ plastic pelletizers, you not only realize economic benefits, but also contribute to environmental protection and work together to build a green, sustainable future.

PP PE HDPE LDPE Plastic Pellets Machine Features

Antecs’ Plastic Recycling Machine is designed with cutting-edge technology to deliver efficient and reliable performance in plastic recycling processes. Here are some key features that set our machine apart:

High Efficiency

Our machine is engineered to maximize throughput while minimizing energy consumption, ensuring efficient plastic recycling operations. It can handle various types of plastic materials, including PP, PE, HDPE, and LDPE, with high efficiency.

Versatility

The machine is versatile and can process a wide range of plastic materials, making it suitable for various recycling applications. Whether you are recycling post-consumer waste or industrial plastic scraps, our machine offers the flexibility to meet your specific needs.

User-Friendly Interface

Antecs’ Plastic Recycling Machine features an intuitive control panel that is easy to operate, allowing users to monitor and control the recycling process with ease. The user-friendly interface reduces the learning curve and increases productivity.

Robust Construction

Built with high-quality materials and components, our machine is designed for durability and long-term performance. It can withstand the rigors of continuous operation in demanding recycling environments, ensuring reliable performance over time.

Advanced Safety Features

Safety is a top priority at Antecs. Our Plastic Recycling Machine is equipped with advanced safety features, including emergency stop buttons, safety guards, and overload protection, to ensure a secure working environment for operators.

Eco-Friendly Design

Committed to sustainability, our machine is designed to minimize waste and energy consumption, aligning with environmental protection goals. By investing in our Plastic Recycling Machine, you are contributing to a greener future by reducing plastic waste and promoting recycling.

PP PE HDPE LDPE Plastic Pellets Machine technical parameters

Here are the technical parameters of Antecs’ Plastic Pellets Machine designed to process PP, PE, HDPE, and LDPE materials

General Specifications

- Machine Type: Plastic Pellets Machine

- Material Compatibility: PP, PE, HDPE, LDPE

- Processing Capacity: [Specify the capacity, e.g., 100-500 kg/h]

Main Features

- Motor Power: [Specify the motor power, e.g., 45 kW]

- Voltage: [Specify the voltage, e.g., 380V, 50Hz]

- Dimension (L x W x H): [Specify the dimensions, e.g., 3500 x 1500 x 2000 mm]

- Weight: [Specify the weight, e.g., 2000 kg]

Operational Parameters

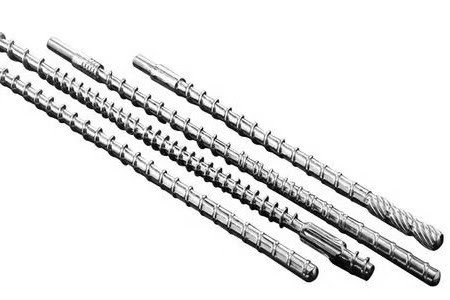

- Screw Diameter: [Specify the screw diameter, e.g., 120 mm]

- Rotation Speed: [Specify the rotation speed, e.g., 60-80 rpm]

- Heating Power: [Specify the heating power, e.g., 15 kW]

Material Requirements

- Material Size: [Specify the maximum material size, e.g., < 10 mm]

- Moisture Content: [Specify the moisture content, e.g., < 5%]

Additional Features

- Control System: PLC control with user-friendly interface

- Safety Features: Emergency stop, overload protection, safety guards

- Cooling System: Air cooling or water cooling system

- Optional Equipment: Pellet cutter, conveyor belt, storage silo

Antecs Plastic Pellets Machine

PP PE HDPE LDPE Plastic Pellets Machine Application Scenario

Antecs' Plastic Granule Machine is designed to provide versatile and efficient solutions for recycling and processing PP, PE, HDPE, and LDPE plastics. Below are some application scenarios where our machine can be effectively utilized.

Plastic Recycling Plants

Our Plastic Granule Machine is ideal for plastic recycling plants looking to process post-consumer waste, industrial scraps, and plastic films into high-quality granules. It helps in reducing plastic waste and promoting a circular economy by transforming discarded plastics into reusable raw materials.

Plastic Manufacturing Industries

Manufacturers in the plastic industry can utilize our machine to produce high-quality plastic granules from virgin or recycled materials. These granules can be used as raw materials for producing various plastic products, including pipes, containers, films, and more.

Waste Management Facilities

Waste management facilities can benefit from our Plastic Granule Machine by converting mixed plastic waste into separated and sorted granules. This process facilitates easier handling, storage, and transportation of plastic materials, contributing to efficient waste management practices.

Research and Development

Our machine is also suitable for research and development purposes, allowing scientists and engineers to experiment with different plastic formulations and recycling processes. It provides a flexible platform for testing new materials and optimizing recycling techniques.

Get a better Plastic Pellets Machine

With 19 years of experience in machinery manufacturing, we will customize machinery to fit your needs.