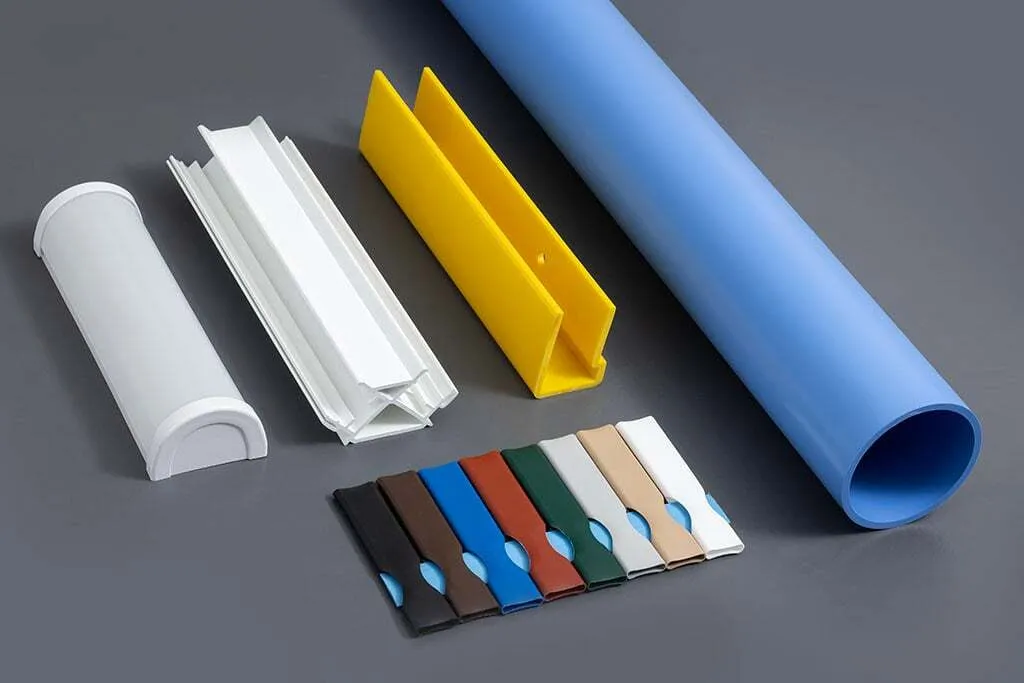

In today’s fast-paced world, we are surrounded by a plethora of plastic products. From everyday household items to industrial components, plastic products are ubiquitous. Among them, plastic profiles are essential raw materials widely used in industries such as automotive, construction, and home appliances. However, as consumer demands for product aesthetics continue to rise, single-color plastic profiles are no longer sufficient. Dual-color or multi-color plastic profiles have gained increasing popularity due to their distinctive visual appeal.

JT Yuyao Plastic Machinery Co., Ltd. (hereinafter referred to as JT Company) has leveraged its years of technical expertise and extensive experience in the plastic machinery industry to specialize in the research and development of dual-color co-extrusion plastic profile production lines. This article will focus on JT Company’s latest JT-45+30B dual-color co-extrusion plastic profile production line, highlighting its advanced design concepts, exceptional manufacturing processes, and unique product performance, showcasing JT Company’s leading position in professional dual-color plastic profile manufacturing.

Advanced Design Concepts

The JT-45+30B dual-color co-extrusion plastic profile production line incorporates JT Company’s years of experience and innovation in the plastic machinery field, embodying advanced design concepts. This production line consists of two single-screw extruders, the JT-45S and the JT-30, each dedicated to extruding different colored plastics, which are then co-extruded through a die to produce dual-color plastic profiles.

JT-45S Single-Screw Extruder

The JT-45S single-screw extruder, equipped with a 11KW permanent magnet servomotor and a matching 11KW servo drive, ensures precise control and consistency during the extrusion process. The extruder features a 45/25 JT 38CrMoAl nitrided barrel and a chrome-plated screw, ensuring durability and efficient material processing. The 133 hardened gear surface gearbox provides reliable power transmission, while the JT-45 PLC control box with a vertical touch screen display in Chinese offers user-friendly operation and precise temperature control.

JT-30 Single-Screw Extruder

The JT-30 single-screw extruder, equipped with a 2.2KW servo gearmotor and a matching 2.2KW servo drive, is responsible for extruding the second color of plastic material. Its 30-type screw barrel ensures optimal material flow and consistent output.

Temperature Control System

Both extruders are equipped with highly precise and energy-efficient CH6 temperature control systems, featuring cast aluminum heaters with three heating zones and forced air cooling fans for efficient heat dissipation.

Exceptional Manufacturing Process

The JT-45+30B dual-color co-extrusion plastic profile production line incorporates advanced manufacturing processes to ensure superior product quality and consistency. The extrusion process begins with the two extruders melting and plasticizing the respective colored plastic materials. The molten materials are then combined and co-extruded through a specialized die to form the desired dual-color profile shape.

Co-Extrusion Process

The co-extrusion process lies at the heart of the JT-45+30B dual-color plastic profile production line. It involves the simultaneous extrusion of two different colored plastic materials through a specialized die to create a single, multi-layered profile.

The molten plastic materials from the JT-45S and JT-30 extruders are fed into separate flow channels within the co-extrusion die. These channels are carefully designed and positioned to ensure that the two materials maintain their distinct separation while being combined into the desired profile shape.

The co-extrusion die plays a crucial role in this process. It is engineered with precision to accommodate the specific requirements of the dual-color profile, such as the number of layers, layer thickness, and the intricate geometry of the final product. The die’s internal flow channels are meticulously crafted to facilitate the smooth and uniform distribution of the two molten materials, preventing any intermixing or distortion.

As the two plastic streams converge within the die, they are fused together under controlled temperature and pressure conditions. This fusion occurs along the interface between the two materials, creating a strong and seamless bond. The resulting dual-color profile emerges from the die in its final shape, with the two distinct colors forming a visually striking and aesthetically pleasing pattern.

The co-extrusion process allows for a wide range of design possibilities, enabling the creation of profiles with intricate color patterns, such as stripes, swirls, or even intricate graphics. The relative positioning and flow rates of the two materials can be adjusted to achieve the desired visual effect, catering to diverse customer preferences and design requirements.

Furthermore, the co-extrusion process offers the flexibility to combine materials with different properties, such as varying degrees of rigidity, impact resistance, or thermal stability. This versatility opens up opportunities for creating profiles with enhanced functional characteristics, tailored to specific applications or environmental conditions.

Vacuum Calibration Table

To maintain a consistent product quality, the production line incorporates a vacuum calibration table. This table uses a water pump, a 1.5KW water-ring vacuum pump, and a stainless-steel water tank and trough to remove any air bubbles or voids from the extruded profile, ensuring a homogeneous and defect-free final product.

Haul-Off Unit

After the calibration process, the dual-color profile is pulled and guided by a haul-off unit. This unit consists of a 1.5KW servo motor, a matching servo drive, a 600mm flat belt, and an adjustable height take-up device. The haul-off unit precisely controls the pulling speed and tension, ensuring dimensional accuracy and preventing deformation of the extruded profile.

Cutting and Cooling System

After the dual-color plastic profile emerges from the co-extrusion die, it enters the cutting and cooling system, which plays a crucial role in ensuring dimensional accuracy and preventing deformation of the final product.

The cutting system, integrated into the production line, is responsible for precisely cutting the continuous extruded profile into desired lengths. It features an encoder-based length measurement system that accurately tracks the profile’s length and triggers the cutting mechanism at predetermined intervals.

The cutting mechanism itself is driven by a 1.5KW servo motor, ensuring precise and repeatable cuts. The cutting unit is mounted on a sliding track, allowing it to move seamlessly along the extruded profile’s path, enabling efficient cutting operations.

Immediately after the cutting process, the individual profile sections are guided through a cooling system. This system is designed to rapidly cool and solidify the extruded profile, preventing any potential deformation or warping due to residual heat.

The cooling system typically consists of a series of water baths or spray chambers, where the profile sections are exposed to a controlled flow of cooling water or air. The cooling medium is carefully regulated to achieve an optimal cooling rate, ensuring that the profile retains its intended shape and dimensions.

In some cases, the cooling system may incorporate additional features, such as vacuum sizing tanks or calibration units, to further refine the profile’s dimensional accuracy. These units apply precise cooling and sizing techniques to ensure that the final product meets the specified tolerances.

The cutting and cooling system works in tandem with the other components of the production line, ensuring a seamless transition from the extrusion and co-extrusion processes to the final product stage. By maintaining dimensional accuracy and preventing deformation, this system plays a crucial role in delivering high-quality, precisely shaped dual-color plastic profiles that meet the stringent requirements of various applications.

Unique Product Performance

The JT-45+30B dual-color co-extrusion plastic profile production line from JT Company offers several unique advantages and benefits, ensuring superior product performance and customer satisfaction.

Aesthetic Appeal

One of the primary advantages of dual-color plastic profiles is their enhanced aesthetic appeal. By combining two different colors in a single profile, manufacturers can create visually striking and distinctive products that stand out in the market. This versatility allows for endless design possibilities, catering to diverse customer preferences and trends.

Functional Benefits

In addition to their visual appeal, dual-color plastic profiles can also offer functional benefits. For instance, one color could be used for the core material, providing structural strength and durability, while the other color serves as an outer layer for aesthetic purposes or additional functionality, such as UV protection or weather resistance.

Customization Capabilities

JT Company’s production line is designed to accommodate a wide range of customization options. Customers can provide their desired samples or drawings, and JT Company’s experienced engineers will work closely with them to develop tailored solutions. This flexibility ensures that the final products meet specific requirements, whether it’s unique color combinations, intricate profile shapes, or special material compositions.

Quality and Consistency

The advanced manufacturing processes employed by JT Company, including the use of high-precision temperature control systems, vacuum calibration tables, and servo-driven haul-off units, ensure consistent and reliable product quality. Each dual-color plastic profile is produced with stringent quality control measures, ensuring dimensional accuracy, homogeneity, and freedom from defects.

Cost-Effectiveness

By combining two different colored materials into a single profile, manufacturers can potentially reduce material costs and streamline production processes. This cost-effectiveness, coupled with JT Company’s efficient production line, allows for competitive pricing without compromising on quality or performance.

Conclusion

The JT-45+30B dual-color co-extrusion plastic profile production line from JT Yuyao Plastic Machinery Co., Ltd. represents a significant advancement in the field of plastic profile manufacturing. With its advanced design concepts, exceptional manufacturing processes, and unique product performance, this production line positions JT Company as a pioneer in professional dual-color plastic profile manufacturing.

Through continuous innovation and a commitment to quality, JT Company aims to meet the ever-evolving demands of various industries, providing high-performance, visually appealing, and cost-effective dual-color plastic profile solutions. Whether for automotive, construction, home appliances, or any other application, JT Company’s expertise and cutting-edge technology ensure that customers receive products that exceed their expectations.